The concept of spherical roller bearings emerges from the fusion of precision engineering and the science of load distribution. In the intricate world of mechanical engineering, where precision and durability intersect, this engineering marvel has transformed the landscape of various industries, from towering wind turbines to the bustling confines of mining equipment.

Exploring the Inner Workings of Spherical Roller Bearings

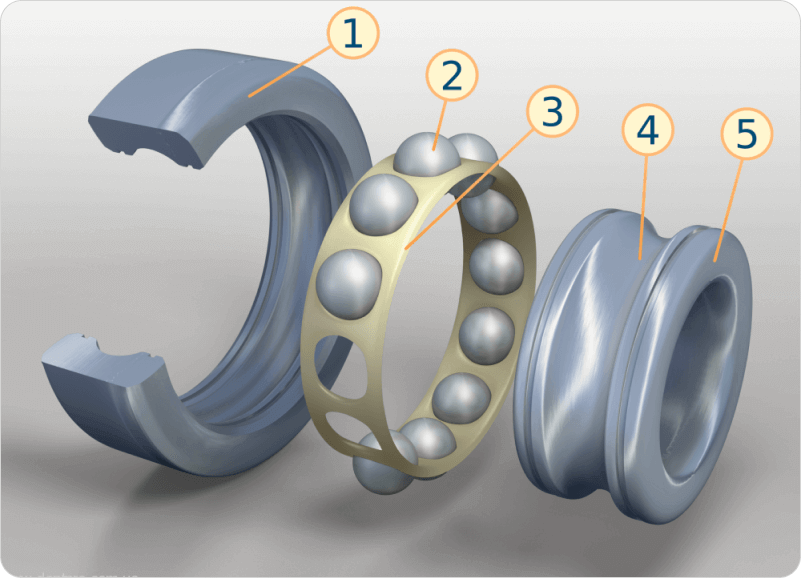

At the heart of a spherical roller bearing lies a symphony of engineering ingenuity. The outer ring embraces concave inner raceways, while the inner ring counters with convex outer raceways, forming a symbiotic sliding surface. This ingenious design birthed various configurations – from the ring-to-ring type like spherical plain bearings and rod ends to the ones equipped with rolling elements nestled between inner and outer rings.

A masterpiece in structural design, spherical roller bearings tout two rows of barrel-shaped rollers. These rollers dance along two internal raceways, strategically angled to accommodate the gyrations of the rotating shaft. The choice of a sealed or unsealed cage offers further versatility, as the construction, heat treatment, and external finish impact the bearing’s performance profoundly. The symmetrical configuration of rollers optimizes load distribution, enhancing longevity, and resilience.

While standardized by ISO regulations in several aspects, the inner characteristics of these bearings remain a manufacturer’s playground. Lubrication methods, the presence of central flanges, central rings, and the application of supporting cages may all be tailored to specific needs. Typically featuring straight bores, spherical roller bearings can even be equipped with tapered bores to align seamlessly with diverse applications.

Bearing the Weight: Robustness and Design

Spherical roller bearings are indomitable forces designed to embrace heavy loads with grace. In scenarios where misalignment is inevitable due to dynamic conditions, these bearings come to the fore. Consider a scenario where a shaft undergoes deflection under high loads. Spherical roller bearings rise to the occasion, withstanding manufacturing tolerances and ensuring seamless operations where conventional ball bearings falter.

Read related content: How to tell if your roller bearings are worn

Diverse Range of Standard Designs: Types of Spherical Roller Bearings

Within the sphere of spherical roller bearings lies a diverse assortment of standard designs, each tailored to distinct industrial requirements:

CC, CA, and E Design Bearings:

Spherical roller bearings come in three fundamental designs: CC, CA, and E. The CC design features stamped window-type steel cages, while CA design boasts a machined double prong-type brass cage. E design, on the other hand, employs stamped window-type steel cages with enhanced load-bearing capabilities.

Sealed Bearings:

Alongside the traditional open bearings, there are sealed spherical roller bearings engineered to meet various application needs. These bearings, furnished with cylindrical bores as standard, are equipped with diverse seal materials like NBR, HNBR, and FKM. These sealed variants cater to scenarios requiring extended lubrication intervals and reduced maintenance hassles.

Spherical Roller Thrust Bearings: Harnessing Asymmetrical Excellence

Venturing into the realm of specialized functionality, we encounter the realm of Spherical Roller Thrust Bearings. These variants boast a distinctive asymmetrical barrel-shaped roller configuration, a key feature that enables them to effortlessly navigate higher loads and speeds. Their primary role revolves around upholding a superior thrust capacity while maintaining consistent alignment. Beyond their practical prowess, these bearings also yield a reduction in friction, amplifying their overall efficiency.

Special Bearings for Vibratory Applications:

Industries relying on vibrating machinery call for specialized bearings. Tailored to withstand the challenges of such environments, these bearings come with C4 radial internal clearance and unique features like PTFE-coated cylindrical bores to combat fretting corrosion. Variants like E/VA405, EJA/VA405, and CCJA/W33VA405 cater exclusively to vibratory applications.

Tailored Bearings for Wind Energy:

Wind turbine main shafts present unique demands, and specialized bearings in the 240 series are crafted to meet these requirements. These bearings, often designated as BC, sport larger diameter rollers, increased contact angles, and a rugged design capable of handling the demands of converting wind into energy.

Custom Solutions to Precision Challenges:

With industries evolving rapidly, there arises the need for bearings that cater to specific, niche requirements:

Bespoke Bearing Solutions:

Leading Bearing manufacturers offer customization options to address distinct industrial challenges. Whether it’s accommodating high speeds, enduring demanding operational conditions, or serving intricate precision machinery, customized spherical roller bearings are meticulously engineered to ensure optimal functionality.

Precision Bearings for High-Speed Scenarios:

In the realm of industrial machinery, where speed is paramount, specialized bearings play a crucial role:

Bearings Engineered for High-Speed Applications:

Spherical roller bearings designed for high-speed applications redefine motion control limits. Identified by the VA991 suffix, these bearings provide a 50% increase in limiting speeds compared to standard counterparts. They find their niche in applications demanding rapid motion, such as multi-megawatt industrial gearboxes.

The Symphony of Features and Advantages

Self-Alignment: Spherical roller bearings possess the remarkable ability to self-align during operation. This self-adjusting feature eliminates the need for specialized tools, ensuring precise centering on the outer race.

Space Efficiency: The compact nature of spherical rollers demands less bearing diameter compared to conventional ball bearings. This efficiency translates to minimized inner and outer race distances, optimizing machinery design.

Load-Carrying Capacity: The cornerstone of spherical roller bearings lies in their unmatched load-bearing capacity. These bearings thrive under extreme conditions, be it temperature fluctuations or vibrations.

Alignment Persistence: Unlike tapered roller bearings necessitating realignment after each use, spherical roller bearings remain steadfast in their alignment throughout their lifecycle, eliminating maintenance hassles.

Silky Operations: The distinctive design of spherical roller bearings yields an extraordinarily smooth operational experience. Their efficiency is a boon across diverse machines and equipment, fostering unhindered performance.

Simplified Maintenance: Spherical roller bearings entail minimal maintenance requirements compared to their counterparts. Routine grease cleaning every six months keeps them in prime condition.

Heavy-Duty Prowess: The spheres of application for these bearings span across earthmoving equipment, mining machinery, industrial apparatus, construction vehicles, marine vessels, and wind turbines, embodying their suitability for heavy-duty tasks.

Also Read: Understanding The Growing Demand For Ball and Roller Bearings In Manufacturing

From Theory to Industry: The Realms of Utilization

Industries around the world are rewriting their operational narratives with the robust presence of spherical roller bearings. What once exceeded the load-bearing threshold of ball bearings now finds solace in the prowess of these advanced constructs. As industries evolve, the application spectrum for spherical roller bearings broadens – from aerospace and automotive to marine and construction. These bearings serve as steadfast allies, defying convention to deliver precision and efficiency.

Their presence graces gearboxes, wind turbines, and continuous casting machines, where reliability and endurance are non-negotiable attributes. Mechanical fans hum to their tune, while mining and construction equipment tirelessly bear their load. In the paper processing realm, they ensure the smooth flow of operations, much like their role in offshore drilling, marine propulsion, and agricultural machinery.

Choose the Best Bearing Manufacturing Company to Improve Your Industrial Efficiency

In the grand tapestry of mechanical evolution, the role of spherical roller bearings is undeniable. Hi-bond Bearings Pvt. Ltd, one of the best bearing manufacturers, with their commitment to excellence, precision, and quality, epitomize the spirit of advancement that drives industries towards greater heights. Their contribution to the evolution of spherical roller bearings cannot be overstated. By crafting bearings that seamlessly balance load capacity, precision, and durability, Hi-Bond Bearings has solidified its position as a cornerstone in the realm of mechanical engineering by providing the best bearings and bushings varieties. Get in touch with us to find the best spherical roller bearing manufacturing company and other bearing and bushings based on your business requirements.

FAQs:

What Are Roller Bearings?

Roller bearings are mechanical components that facilitate smooth motion between surfaces. They minimize friction and enable rotation or linear movement. Unlike plain bearings, roller bearings use cylindrical, tapered, spherical, or needle-shaped rollers between inner and outer rings. These rollers distribute loads evenly, reducing friction. Roller bearings are crucial in industries like automotive and aerospace for their ability to handle loads efficiently.

What is a Spherical Roller Bearing?

A spherical roller bearing is a specialized type with barrel-shaped rollers. These rollers rotate along the inner ring’s raceway and adapt to the outer ring’s spherical surface. They have several benefits:

Load Capacity: Barrel-shaped rollers distribute loads evenly, making them suitable for heavy-duty tasks.

Misalignment Tolerance: They handle misalignment between shaft and housing, ensuring smooth operation even when not perfectly aligned.

Radial and Axial Loads: These bearings handle both types of loads, making them versatile for various machinery.

Durability: Spherical roller bearings ensure rigorous conditions, ideal for industries like mining and heavy manufacturing.

Variety: They come in different designs, tailored to specific loads, speeds, and conditions.

These bearings find use in conveyors, heavy machinery, mining, and power generation. By combining load-bearing capacity and adaptability to misalignment, they enhance machine performance and longevity.