When it comes to the intricate world of machinery, one component that often goes under the radar but plays a pivotal role is bearings. Bearings come in various types, but today, we’re delving into the distinctions between plain bearings and ball bearings. Understanding these differences can help you make the right choice for your specific application.

Plain Bearings: The Foundation of Stability

Let’s start by dissecting plain bearings. These workhorses consist of two essential parts: a stationary housing and a rotating shaft. The shaft can either be supported by an internal or external surface, depending on the design. Plain bearings shine in engineering applications where high load capacity and low speed are paramount.

There’s a plethora of plain bearing types, including sleeve, thrust, flange, and self-aligning designs, each crafted to meet unique requirements. Material-wise, they can be made from bronze, steel, aluminum alloy, or plastic, with some featuring anti-friction coatings to minimize wear and tear.

The key parameters for plain bearings are stiffness, load capacity, and rotational speed capabilities. Picking the right combination ensures optimal performance and a long lifespan. For instance, excessive flexibility can lead to premature failure, while inadequate load capacity might damage the housing over time.

Plain bearings offer several advantages, including cost-effectiveness, superior wear resistance, and ease of installation. However, they require consistent lubrication for proper function and longevity.

Read More: How Does the Use of Ball Bearings Reduce Friction?

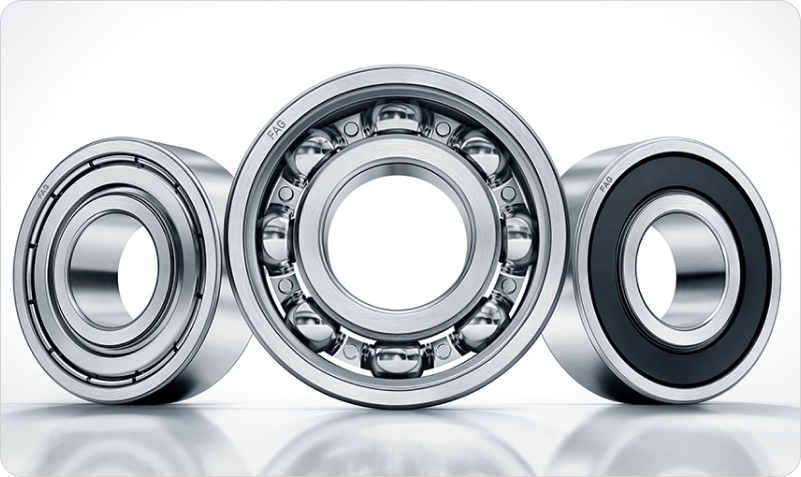

Ball Bearings: Precision in Motion

Now, let’s shift our focus to ball bearings. These engineering marvels utilize multiple balls enclosed in steel cages to maintain separation between moving parts. Ball bearings find their homes in applications like hard drives, roller skates, and door hinges, thanks to their ability to reduce rotational friction and support both radial and axial loads.

Ball bearings come in various types, including angular contact, deep groove radial, and self-aligning spherical and cylindrical variations. Depending on the design, they can handle thrust and radial loading simultaneously. Speed capabilities depend on factors like lubrication conditions and load levels.

Ball bearings outshine their plain counterparts in terms of performance, handling higher loads at faster speeds with reduced noise levels during operation.

Types of Plain Bearings: Variety for Versatility

Plain bearings aren’t a one-size-fits-all deal. They come in various types to cater to diverse machine needs. The selection includes sliding contact or journal bearings, sleeve bearings, and flanged-sleeve bushings. Material selection varies depending on the application, with options like bronze alloys, cast iron, steel, sintered metals, and plastics. Surface treatments like heat treatment or electroplating may be applied as needed.

Selecting the right plain bearing type involves considering factors such as load capacity, fatigue life, and lubrication requirements. Environmental conditions, including temperature, moisture, and vibration, must also be factored in. In some cases, custom-designed components may be necessary to meet specific performance criteria.

Proper lubrication is crucial for plain bearing longevity. Grease-based lubricants and oil-lubricated bearings each have their pros and cons, requiring careful selection based on the application’s demands. Contamination issues must also be addressed to maintain bearing integrity.

Types of Ball Bearings: Diverse and Efficient

Ball bearings come in various types, each tailored to different needs:

Roller Bearing: Featuring cylindrical rollers in inner and outer rings, they provide smooth, low-friction rotation and can handle heavy loads.

Needle Bearing: Rows of needles between two rings reduce frictional resistance and offer high load capacity.

Thrust Bearing: With flat surfaces for axial movement in one direction.

Spherical Bearings: Ideal for angular misalignment between shafts during rotation or vertical movement.

Angular Contact Bearing: Designed for applications requiring radial loading along with axial load support.

Recommended: A Comprehensive Guide to Journal Bearings vs. Thrust Bearings

Structure and Design Comparison: Unveiling the Inner Workings

Comparing plain bearing and ball bearing structures reveals significant differences. Plain bearings consist of a shaft rotating within a housing lined with materials like bronze, plastic, or metal. These bearings are designed to contain lubricant, preventing wear from contact between components.

Ball bearings, on the other hand, feature inner and outer rings with balls that reduce friction during rotation. Steel rings filled with ceramic-coated balls minimize friction. The precision design of ball bearings increases load capacity compared to plain bearings.

Load Capacity Comparison: A Weighty Matter

Load capacity is a crucial consideration. Plain bearings excel in this department due to their larger contact area, distributing weight evenly across the surface. Materials like bronze or harder materials can increase load capacity.

Ball bearings, with multiple points of contact, have lower overall load capacity but offer higher speed capabilities and reduced noise during operation.

Speed Limitations Comparison: The Need for Speed

Speed matters. Plain bearings rely on friction and are limited by it. Ball bearings, in contrast, allow for higher rotation velocity due to less friction generated from rolling elements instead of sliding surfaces.

Durability and Maintenance Comparison: Longevity Matters

Plain bearings require more maintenance due to moving parts that need regular inspection and replacement. Ball bearings demand meticulous care to prevent contamination and maintain performance.

Cost Comparison: Balancing Budgets

Plain bearings are generally more cost-effective upfront, making them attractive for budget-conscious projects. Ball bearings come at a higher initial cost but offer efficiency and longevity benefits.

Advantages and Disadvantages: Weighing the Pros and Cons

- Plain bearings offer simplicity, low cost, high load capacity, wear resistance, self-lubrication, and shock tolerance. However, they have higher friction, alignment challenges, and limited speed.

- Ball bearings excel in precision, reduced friction, speed, lower noise, and misalignment tolerance. But, they can be costlier, require more maintenance, and have potential corrosion issues.

Choosing the Right Bearing: A Delicate Balance

In conclusion, the world of bearings is diverse, with plain bearings and ball bearings serving distinct roles in various applications. When seeking reliable and high-quality bearings and bushings, Hi-Bond Bearings Pvt. Ltd emerges as a top choice. With a rich legacy spanning over 35 years, Hi-Bond has established itself as a premier bearing and bushing supplier, excelling in both plain and ball bearings. Their commitment to excellence and unwavering dedication to quality positions them as trusted bearing manufacturers in the industry. For all your bearing and bushing needs, visit Hi-Bond Bearings and Bushes, your source for premium solutions.