The demand for ball and roller bearings is increasing rapidly. As technology advances and the need for more efficient machines grows, so does the demand for these components.

But what exactly makes these components so crucial to the success of modern-day production?

This blog post will explore why there is a rising demand for ball and roller bearings, and how you can take advantage of this trend to grow your business.

We’ll look at:

- What are Ball and Roller Bearing

- Why the Rising Demand

- Advantages of Using Ball & Roller Bearings

- How to Choose the Right Bearing for Your Needs

- The various types of bearings available today

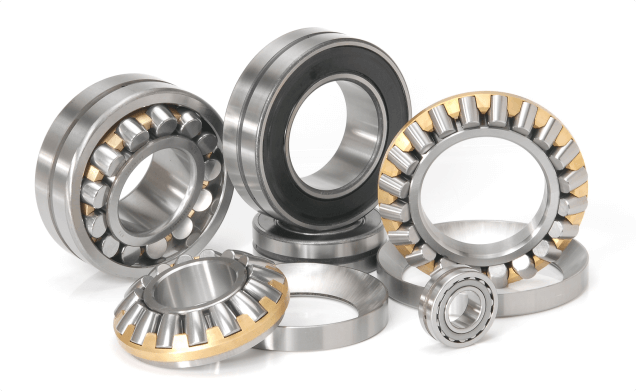

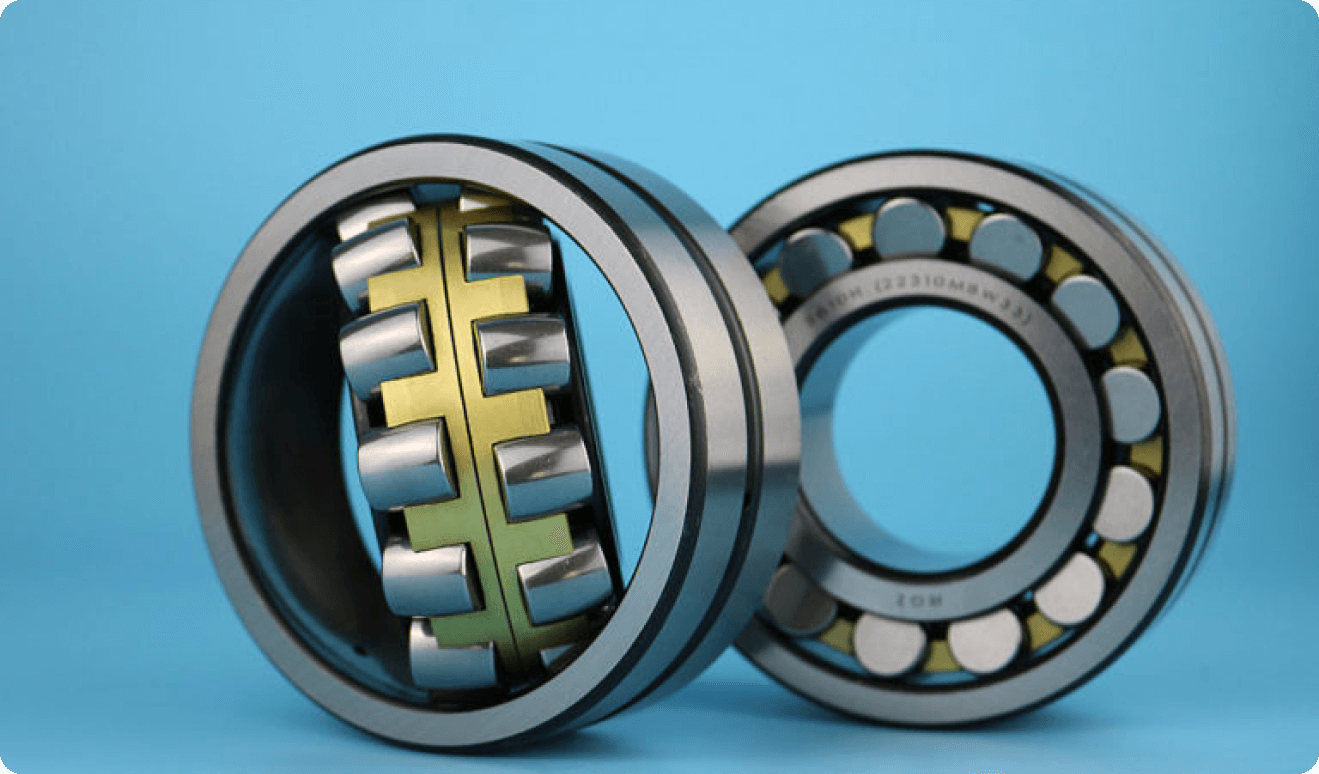

What are Ball and Roller Bearings?

Ball & roller bearings are one of the most common types of bearings used in manufacturing. They are typically used to support rotating shafts, control rotating speeds and reduce friction between moving parts. Ball & roller bearings are available in a variety of sizes and designs to suit a wide range of applications.

They are commonly used in conveyor belts, pumps, fans, and gearboxes. Ball & roller bearings can also be found in a wide range of industrial machinery, from lathes and milling machines to cranes and presses.

The Rising Demand:

The twentieth century saw a range of advancements in smart bearings, from increased choice for rolling elements to the capacity to support combined loads.

According to Fortune Business Insights, Global Bearings Market Size is projected to reach to USD 52.44 billion by 2026 at a CAGR of 3.6% during forecast period 2019-2026; Increasing Demand for Precision Bearing is expected to drive the Bearing Market.

Swedish engineer Sven Winquist is particularly credited for his design of self-aligning ball bearings which set a new benchmark in terms of developing the technology, and sparked successive inventions such as the wire race bearing and deep groove bearing.

With growing demand for specialized ball bearings, specialty companies were created, further solidifying its place with the establishment of ABMA (American Bearing Manufacturers Association) who introduced a numbering system still used in global production today.

In a nutshell, the growing demand for bearing manufacturing is driven by several factors.

The continued expansion of global trade is opening up new markets for manufacturers who use these components in their products. At the same time, advances in technology are leading to more sophisticated applications for ball & roller bearings.

As manufacturing processes become more automated, there is an increasing demand for components that can handle higher loads and speeds without fail. Ball & roller bearings offer superior performance under these conditions, making them an essential part of modern manufacturing processes.

There are two main types of ball and roller bearings: rolling-element bearings and plain bearings. Rolling-element bearings use rolling elements (balls or rollers) to support the load, while plain bearings rely on friction between the bearing surface and the shaft or housing.

Ball and roller bearings are used in a variety of applications, including:

- Automotive Industry: Bearings are used in a variety of automotive applications, including wheels, transmissions, axles, and drive shafts.

- Aerospace: Bearings are used in aircraft engines, landing gear, and flight control systems.

- Food processing: Bearings are used in food-processing equipment such as conveyors, mixers, grinders, and packaging machines.

- Energy production: Bearings are used in wind turbines and oil rigs.

Read More: How Does the Use of Ball Bearings Reduce friction

Advantages of Using Ball & Roller Bearings

There are several advantages of using ball and roller bearings in manufacturing.

- They allow for smoother operation of machinery, reduced noise levels, and increased efficiency. Ball and roller bearings also have a longer lifespan than other types of bearings, which reduces maintenance costs and downtime.

- One of the biggest advantages of using ball and roller bearings is that they allow for smoother operation of machinery. This is because the balls or rollers rotate smoothly within the bearing, without any friction. This results in less wear and tear on the machinery, as well as reduced noise levels.

- Ball and roller bearings also have a longer lifespan than other types of bearings. This is because they are designed to withstand higher loads and speeds. This means that they will last longer before needing to be replaced, which reduces maintenance costs and downtime.

Recommended reading: How Tell If You Roller Bearings are Worn

How to Choose the Right Bearing for Your Needs

There are a few things to consider when choosing the right bearing for your needs.

- The first is the type of load that the bearing will be subject to. Bearings are designed to handle different types of loads, so it’s important to choose one that can handle the type of loads you’ll be subjecting it to.

- Another thing to consider is the environment the bearing will be operating in. Some bearings are designed for specific environments, so it’s important to make sure you choose one that can withstand the conditions it will be operating in.

- Finally, you need to consider the size and weight of the bearing. This will determine how much load it can handle and what type of mounts you’ll need to use.

Hi-Bond Bearings: Your Experienced Bearing Supplier

If you are looking to find the best bearing supplier near you, then you’ve come to the right place. Our offerings include:

- White metal bearings are bearings that are made of a white metal alloy, typically composed of tin, copper, and antimony. They are known for their high load-carrying capacity and resistance to wear, making them suitable for use in heavy-duty machinery and equipment.

- Half bearings are bearings that are only partially encased in a housing, leaving one side exposed. They are typically used in applications where space is limited, and they offer a cost-effective solution for situations where full-encased bearings would be too large or too expensive.

- Flange bearings are bearings that have a flange on one or both sides of the bearing. The flange helps to keep the bearing securely in place and can also be used to mount the bearing to other equipment.

- Tri metal bearings are bearings that are made of a combination of three metals, typically a steel backing, a lead-based intermediate layer, and a tin-based overlay. They are known for their high load-carrying capacity and resistance to wear, and they are often used in high-temperature and high-pressure applications.

- Journal bearings are bearings that are used to support rotating parts, such as shafts and axles. They are typically composed of a metal sleeve and a lubricant, and they work by reducing friction between the rotating part and the bearing.

Find the Best Bearing manufacturers Near You

As the manufacturing industry evolves and technological advancement continues, so does the demand for high performance bearings. It’s clear to see that these components have a variety of applications and are essential in many different industries.

Understanding why there is an increased need for this type of bearing is key in order to make informed decisions when it comes to purchasing them. With greater knowledge of their uses, companies can ensure they get the right product from the best bearing manufacturing company at competitive prices that meets their specific needs.

At Hi-bond Bearings Pvt. Ltd, one of the best bearings and bushes suppliers, we deliver the very best high performance bearings for specialized and every-day use. Get in touch with us today to know more.