Bearing and bushing suppliers often use a wide range of materials for their products, including bronze, brass, and copper. These three metals are commonly used to manufacture bearings and bushings due to their excellent mechanical properties and durability.

However, despite their similarities, significant differences between the three metals affect their performance in various applications.

Understanding the unique characteristics of each material is crucial for selecting the right bearing and bushing for a particular bearing or bushing application.

This blog will delve deeper into the differences between bronze, brass, and copper and their suitability for bearing and bushing applications.

Read more: How Does the Use of Ball Bearings Reduce Friction?

Bronze

Bronze is an alloy made of copper, tin, and other metals, such as zinc, lead, and nickel. The exact composition of bronze can vary, which affects its properties. Bronze is a hard, strong, durable material that resists corrosion and wears. In addition, it is a beautiful golden-brown color often used for decorative purposes.

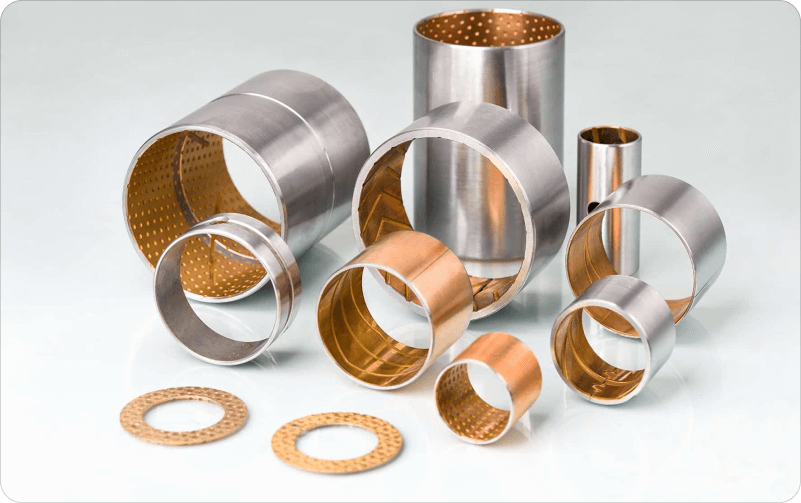

Bronze is often used in applications requiring strength and durability, such as bearings and bushings. As a result, bronze bushes are widely used in industrial and manufacturing settings. Bearings and bushings suppliers offer a range of bronze bushes, including oil-impregnated bronze bushes and self-lubricating bronze bushes.

Brass

Brass is an alloy made of copper and zinc. Like bronze, the exact composition of brass can vary, which affects its properties. Brass is a soft and malleable material that is easy to shape and work with. It has a yellowish-gold color that can range from bright to dull.

Brass is often used in applications requiring strength and beauty, such as decorative hardware, musical instruments, and plumbing fixtures. It is also used in bearings and bushings, although less frequently than bronze.

Copper

Copper is a pure metal that is soft and malleable. It has a distinctive reddish-orange color that is often used for decorative purposes. Copper is an excellent conductor of electricity and heat, which makes it ideal for electrical wiring and plumbing.

Copper is often used in electrical conductivity applications, such as electrical wires and motor windings. It is also used in plumbing fixtures and decorative accents.

Differences between Bronze, Brass, and Copper

While bronze, brass, and copper share similarities, they differ in composition and properties. The following are the main differences between these three materials:

Composition

The exact composition of bronze can vary, which affects its properties. Brass is an alloy of copper and zinc, with varying amounts of these metals depending on the brass’s intended use. Copper is a pure metal, which means it is not an alloy and is made up of only one type of metal.

Strength and Durability

Bronze is known for its strength and durability, making it ideal for use in applications requiring high hardness, such as bearings and bushings. Bronze is harder than brass and copper, making it more resistant to wear and corrosion over time. Brass is not as strong as bronze, but it is still a relatively durable metal that can withstand regular use in many applications. Copper is the weakest of the three metals, making it less suitable for high-stress applications.

Malleability

Brass is the most malleable of the three metals, meaning it is the easiest to shape and work with. Copper is less malleable than brass but is still relatively easy to manipulate. Bronze is the least malleable of the three metals, making it more difficult to shape or work with.

Color

Each of these metals has a distinctive color often used in decorative applications. For example, bronze is a golden-brown color often used in sculptures, statues, and other decorative objects. Brass is a yellowish-gold color popular in jewelry, decorative hardware, and musical instruments. Copper is a reddish-orange color often used in electrical wiring and plumbing.

Magnetism

Copper and brass are non-magnetic materials that do not attract or repel magnets. Conversely, bronze can be either non-magnetic or weakly magnetic, depending on its composition.

Recommended Reading: Understanding the Growing Demand for Ball & Roller Bearings in Manufacturing

Price

Copper is the most affordable of the three materials due to its natural abundance. However, brass is generally more expensive than copper, and bronze is typically the most expensive due to its strength and durability.

Heat resistance

Bronze has a higher melting point than brass and copper, making it more heat-resistant. On the other hand, copper has a relatively low melting point, and brass falls in between copper and bronze.

Conductivity

Copper is an excellent conductor of electricity and heat, making it ideal for electrical and thermal applications. Bronze and Brass are also good conductors of electricity and heat, but copper is more efficient.

Applications

Each of these metals has its own unique set of properties that make it ideal for specific applications. For example, bronze is commonly used in bearings, bushings, and other industrial and manufacturing settings where strength and durability are essential. Brass is often used in decorative hardware, musical instruments, and plumbing fixtures. Copper is widely used in electrical wiring, plumbing, and other applications where its high electrical conductivity is beneficial.

How does Copper, Bronze & Brass help in Bearing & Bushing Manufacturing?

Copper, bronze, and brass are widely used in the manufacturing of bearings due to their excellent thermal conductivity, high corrosion resistance, and exceptional wear resistance. Copper-based alloys are highly ductile and possess excellent shock and vibration resistance, making them ideal for use in bearings that undergo high stress and strain.

Bronze bearings are highly recommended for applications that require high-load carrying capacity, low friction, and resistance to wear and fatigue. The addition of tin to copper creates bronze, which is much stronger than copper and has better corrosion resistance. Bronze bearings are used in numerous applications, including marine, aircraft, and heavy industrial machinery.

Brass bearings, on the other hand, are popular for their low friction coefficient, good thermal conductivity, and corrosion resistance. They are used in high-speed applications, such as electric motors and machinery, where low friction is essential for efficient operation. Brass bearings are also used in applications where low loads and speeds are required.

Find the Best Bronze, Copper & Bronze Bearing Suppliers/ Manufacturers Near You

Bronze, brass, and copper are common materials used in various applications. While they may look similar, each has unique properties that make them ideal for specific purposes.

Bushing suppliers, Bearings suppliers, and manufacturers often use bronze, brass, and copper bushes for applications requiring strength and durability.

Choosing the right material is crucial when manufacturing high-quality ball bearings and bushings.

Hi-bond, the best bearing manufacturing company, uses the finest materials to ensure our ball bearings are strong, durable, and withstand the toughest conditions. With years of experience and a commitment to excellence, Hi-bond Bearing manufacturer is the perfect choice for anyone needing reliable, high-quality ball bearings.

Get in touch with us today to learn more about our products.