We’ve all heard that industrial bearings reduce friction in machinery, but have you heard of flange bearings? These bearings have a special design and are engineered by dedicated flange bearing manufacturers to meet specific requirements. Their sturdiness, water resistance, and dirt resistance make them ideal for mounting in rotary or linear motion applications.

Many prefer flange mounted bearings because the shaft axis is perpendicular to the mounting surface. These bearings are not only easy to replace, but they can also handle heavy loads and provide protection against deflection and damage caused by vibration.

Keep reading our guide to learn about the flange bearing types, applications, their exceptional features, and more. Hi-bond Bearings Pvt. Ltd, your trusted flange bearing manufacturers, leads the way towards bearings that improve the performance and durability of your machinery.

What is a Flange Bearing?

In simple terms, flange bearings are specialized bearings with a cool lip or rim around the edge designed to provide stability and protection. They contain smooth balls that roll between races, acting like train tracks to guide movement.

A flange bearing consists of an inner race, an outer race, and sometimes a cage assembly. These bearings serve various industries by ensuring the smooth and reliable operation of machinery.

Flange Bearings vs. Standard Bearings – The Key Difference

Now, let’s talk about the difference between flange bearings and standard bearings. Both types of bearings have balls and tracks, but flange bearings have that special flanged design we mentioned earlier.

Their design differs because flange bearings have a lip or rim called a flange, while standard bearings are smooth without a flange. The flange in flange bearings is located on the outer race that provides a tighter and more secure fit. This design is useful in various applications where stability and precise positioning are important.

The Design of Flange Bearings

Flange bearings come in various types, models, and variations, but they can be categorized into two main structures: vertical mounting (insert bearings) and horizontal mounting (flange mounted bearings). Each structure serves different purposes with varying load carrying capacity and performance.

When selecting a flange bearing, it’s essential to consider the bearing size, including the shaft size that determines the maximum diameter and the height above the bearing mounting surface, particularly for applications with limited clearance.

The Applications of Flange Bearings

Flange bearings have extensive use in a wide range of industries and machines. They are widely employed in automation, machine construction, agricultural machinery, the food industry, conveyor technology, and other sectors that require high carrying capacity.

These bearings are essential in supporting heavy loads and ensuring smooth operation in various industrial applications. They are a reliable choice for industries that demand robust and efficient bearing solutions.

What are The Types of Flange Bearings?

Four different flange bearing types are used, each with a unique design, application, performance, and function. These bearings are essential for providing smooth rotary motion with minimal friction.

Here are the few types of bearings commonly used in flange bearings:

Plain Bearings (Journal Bearings)

Also known as journal bearings, plain bearings offer frictionless motion, making them ideal for linear applications.

Needle Roller Bearings

These bearings handle radial motion while maintaining a low profile. They are identical to cylindrical roller bearings but have a smaller diameter.

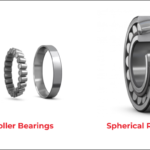

Roller Bearings

Depending on the application, roller bearings have a rolling element between their inner and outer ring which can be a cylindrical, tapered or spherical ball.

- Cylindrical Roller Bearings: These bearings have a high radial load capacity and can handle moderate thrust loads.

- Spherical Roller Bearings: The most common roller bearings used in flange mount bearings contain two rows of friction-reducing, barrel-shaped rollers between an outer ring that has a spherical raceway and an inner ring composed of two inclined raceways.

- Tapered Roller Bearings: With an inner ring, outer ring, and tapered rollers, these bearings can withstand heavy axial and radial loads due to their large surface area contact.

- Needle Roller Bearings: These bearings have a smaller diameter-to-length ratio and are designed for radial load applications where a low profile is desired.

Plain Bearings (Flanged Sleeve Bearings)

Also known as bushings or journal bearings, plain bearings work through sliding action instead of rolling action. They are used to constrain, guide, or reduce friction in rotary or linear applications. Proper lubrication is crucial to prevent overheating caused by friction.

It is always best to consult our expert bearing manufacturing company and select the appropriate bearing type for specific flange bearing applications.

Material Used in Flange Bearing

Flange bearing manufacturers make the use of various materials to suit different requirements.

- Cast iron is a commonly used material due to its temperature resistance, durability, and stability.

- Plastic is also utilized by some flange bearing manufacturers to reduce costs while maintaining performance and load carrying capacity.

- Pressed steel is rarely used to offer high stability and durability, even in challenging conditions.

Mounting of a Flange Bearing

The mounting configuration of bearings with flange is crucial in securing the bearing and maintaining alignment. There are three commonly used mounting configurations for flange bearings:

- 2 Bolt Flange Bearings: These bearings have a diamond shape and feature one mounting hole on each end. When mounted, a straight line drawn through the axis of the mounting holes aligns with the axis of the bearing.

- 3 Bolt Flange Bearings: These bearings are circular and equipped with three mounting holes. The holes are arranged radially near the bearing axis at 120° from each other or placed on a triangular flange offset from the bearing axis.

- 4 Bolt Flange Bearings: These bearings are typically square and come with four mounting holes. The holes are located radially around the bearing axis, providing a secure attachment. Four-bolt flanged bearings can have round or square housings, depending on the application or requirement.

Each bearing mounting configuration offers specific stability, alignment, and load distribution advantages for various applications.

Bearing and Housing Features You Must Know

Flange bearings come with different features that cater to specific needs:

- Offset Hole Pattern: Found in 3-bolt flanges, the offset holes differ from the radially symmetrical pattern and offer unique mounting options.

- Spherical/Self-aligning Bearings: Available in internal and external types, these bearings allow for minor shaft/bearing misalignments, enhancing flexibility in usage.

- Split Bearing Housing: Some bearings and housings are split into two pieces and bolted together, facilitating easier maintenance or bearing replacement for worn or damaged bearings or shafts.

- Shaft Securing Method: Bearings can be secured to the shaft using set screws, locking collars, or no securing method, each offering distinct advantages.

These features play an important role in the performance and maintenance of flange bearings.

Performance Specifications for Flange Mounted Bearings

There are some specifications to consider when selecting a flange mounted bearing:

- Maximum Speed: The high speed at which the bearing can safely function before failure, influenced by load characteristics, bearing lubrication, and temperature.

- Bearing Life: A statistical measure of the life that 90% of a group of apparently identical flanged ball bearings will achieve or exceed, also known as the rating life L10.

- Bearing Loads: These are a combination of radial loads and thrust forces, requiring careful consideration based on the magnitude of the thrust force.

- Basic Dynamic and Static Load Ratings: Calculated constant radial load and uniformly distributed load for a ball bearing.

These specifications are essential for determining the suitability and longevity of flange mounted bearings in various applications.

Lubrication Needs for Flange Bearings

Proper lubrication is essential for reducing wear and friction in bearings. Flange bearings can be lubricated using different methods:

- Manual Lubrication: Utilizes a pump or a grease fitting mounted on the housing for delivering lubrication to the friction points of the flange bearing.

- Self-lubricating Bearings: These are constructed of materials such as oil-impregnated bronze or graphite/metal alloy, eliminating the need for external lubrication.

Our bearing manufacturing company will guide you best in choosing the right lubrication method necessary for ensuring the longevity and performance of flange bearings.

Factors to Consider When Choosing Flange Bearings

When choosing flange bearings, we help customers decide on various factors to make sure that they meet the specific requirements of your application.

Material Composition

Flange bearings are typically composed of multiple materials. For instance, the cage may be made of nylon or acetal, while the balls could be constructed from ceramic or glass. The material composition is crucial for assessing the suitability of bearings for specific environmental conditions and load requirements.

Corrosion Resistance

If the intended application involves exposure to corrosive chemicals, opting for non-corrosive flange bearings is imperative. These bearings are designed to withstand corrosive chemicals without degrading, ensuring longevity and performance in challenging environments.

Flange Size

The size of the flange, which is a uniform lip running along the exterior of the outer race, is an important consideration. Flange bearings come with varying flange sizes, with some featuring a large flange and others having a slimmer flange. Selecting the appropriate flange size based on the specific application requirements is essential for ensuring optimal fit and performance.

When choosing flange bearings, you must seek assistance from our expert bearing and bushes suppliers. We can provide valuable recommendations based on material composition, corrosion resistance, and flange size.

Consider these expert-recommended factors and select the right flange bearings that effectively meet the needs of the intended application.

Experience the Future of Flange Bearings with Hi-bond!

With extensive experience in the market, Hi-bond Bearings Pvt. Ltd stands as the leading bearings and bushes suppliers. Our focus on innovation drives us to push the boundaries of flange bearings. These bearings are ideal for vertical shaft axis applications, offering easy removal and replacement.

Get this opportunity to experience the future of bearing technology with us. Contact Hi-bond today for innovative flange bearing solutions that meet and exceed your expectations.