Choosing the right bearing can feel like navigating a labyrinth of acronyms and technical jargon. But fear not gearheads! Today, we’re taking the mystery out of two powerhouse players in the bearing world: Tapered Roller Bearing vs. Spherical Roller Bearing. Get ready to dive into the deep end of load capacities, misalignment tolerance, and the nitty-gritty of how these champions of rotation keep the industrial world humming

Whether you’re a seasoned engineer navigating complex machinery or a curious tinkerer building your dream workshop cart, understanding the nuances of Tapered Roller Bearing vs. Spherical Roller Bearings and finding the best bearings and bushes suppliers will empower you to make informed decisions and keep your projects spinning smoothly. So, buckle up, grab your grease rag, and let’s delve into the thrilling world of bearing mechanics!

What is Tapered Roller Bearings?

Tapered roller bearings embody a specialized design featuring tapered rollers positioned amidst inner and outer ring raceways. These rollers are engineered with inner and outer ring raceways and rollers that converge at a singular point along the bearing axis, creating conical apices. These bearings utilize trapezoidal tapered rollers guided by a substantial rib on the inner ring.

Benefits of Tappered Roller Bearings

- High Load-Carrying Capacity: Noteworthy for their capacity to support substantial loads owing to a larger contact area facilitated by their tapered design.

- Precision and Operational Accuracy: Famed for precision, ideal for applications demanding meticulous control over bearing movements and loads.

- Handling Axial and Radial Loads: Versatile in managing both axial (thrust) and radial loads, a unique trait derived from their design.

Common Applications of Tapered Bearings

Automotive Industry

- Car Wheel Bearings: Both tapered and spherical roller bearings are used, with tapered bearings preferred for their ability to handle combined radial and axial loads in high-speed applications. For independent suspension systems, spherical roller bearings can provide better misalignment tolerance.

- Drivetrain Components: Tapered roller bearings are often found in transmissions, differentials, and propeller shafts due to their high load capacity and ability to handle both radial and axial forces.

- Steering Systems: Spherical roller bearings can be found in steering linkages and columns due to their ability to accommodate misalignment from road imperfections and maneuvering.

Heavy Machinery

- Construction Equipment: Tapered roller bearings are crucial in excavators, loaders, and bulldozers for their exceptional load capacity and resistance to shock loads. Spherical roller bearings can be found in applications with high misalignment, like bucket linkages and slewing rings.

- Mining Equipment: Both bearings are used in crushers, mills, and conveyors due to their durability and ability to handle harsh environments and heavy loads. Tapered bearings handle combined loads, while spherical bearings accommodate misalignment in rotating components.

Agricultural Equipment

- Tractors and Combine Harvesters: Tapered roller bearings are used in axles, gearboxes, and PTO shafts due to their high load capacity and resistance to dust and dirt. Spherical roller bearings can be found in steering systems and implement linkages for their misalignment tolerance.

- Tillage Equipment: Both bearings are used in plows, cultivators, and planters due to their ability to handle heavy loads and resist wear and tear in demanding soil conditions.

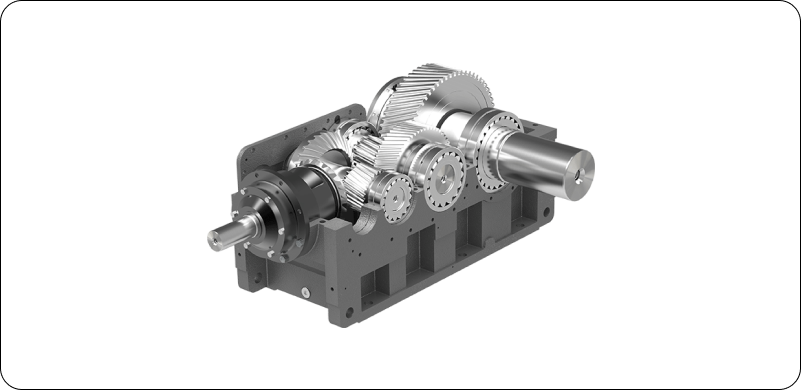

Industrial Gearboxes

- High-Precision Gearboxes: Tapered roller bearings are favored for their precise alignment and ability to handle heavy loads with minimal deflection, crucial for maintaining gear mesh and efficiency. Spherical roller bearings can be used in situations with slight misalignment or where shock loads are present.

- Heavy-Duty Gearboxes: Both bearings are found in applications like wind turbines, paper mills, and rolling mills due to their exceptional load capacity and durability. Tapered bearings handle combined loads, while spherical bearings tolerate misalignment.

Limitations in Specific Use Cases

- Speed Limitations: Might not suit high-speed applications due to design constraints.

- Misalignment Sensitivity: Sensitivity to misalignment necessitates meticulous installation and maintenance.

- Mounting and Disassembly Complexity: Internal design complexity leads to intricate mounting and disassembly procedures compared to other bearing types.

What is Spherical Roller Bearings?

Spherical roller bearings feature a unique design with two rows of barrel-shaped rollers oriented diagonally across inner and outer raceways. This design allows adjustment to varying alignment degrees and load directions, showcasing their versatility.

Benefits of Spherical Bearings

- Self-Alignment Capability: Unique ability to self-align, derived from the curvature of the outer ring raceway, aligning with the rotational axis.

- Exceptional Load Capacity: Designed to handle high radial loads and moderate axial loads, ideal for heavy-duty applications.

- Misalignment Tolerance: Ability to tolerate certain degrees of misalignment, compensating for shaft deflection and alignment errors without compromising performance.

Typical Use Cases

Heavy Machinery

- Mining Equipment: They can handle the extreme loads and shock encountered by excavators, dump trucks, and crushers.

- Construction Machinery: From bulldozers and cranes to pavers and mixers, these bearings ensure smooth operation and extended equipment lifespan.

- Agricultural Machinery: Tractors, harvesters, and other heavy farm equipment rely on them for durability and resistance to harsh environments.

Wind Turbines

- Main Shafts: Their ability to handle combined loads and misalignment makes them vital for transferring massive rotor forces to the gearbox.

- Yaw Drives: They enable the turbine to track wind direction efficiently, ensuring optimal power generation.

- Pitch Bearings: These specialized bearings allow blades to adjust their angle for maximum wind capture while withstanding varying loads.

Paper Mills

- Pulp Refiners: Their high load capacity and resistance to contamination are crucial for processing fibrous materials efficiently.

- Calenders: The precise roller alignment provided by these bearings guarantees consistent paper thickness and smoothness.

- Drives and Rolls: They ensure smooth operation and minimize downtime in the demanding high-pressure environment of papermaking.

Gearboxes and Pulleys

- Large Industrial Gearboxes: Their ability to handle combined radial and axial loads is essential for power transmission in gearboxes across various industries.

- Pulley Systems: They accommodate misalignment in belt drives, preventing wear and tear and ensuring efficient power transfer.

- High-Speed Applications: Some specialized types are designed for high-speed operations, making them ideal for applications like textile machinery and printing presses.

Read More: Spherical Roller Bearings: A Comprehensive Guide

Limitations and Constraints

- Speed Limitations: Might not be the best choice for high-speed applications despite handling heavy loads.

- Complexity and Cost: Advanced design complexity can lead to higher costs and complexity compared to simpler bearing types.

- Size and Weight: Generally larger and heavier, which might pose constraints in applications with space or weight limitations.

Tapered Roller Bearing vs. Spherical Roller Bearing: An Overview

| Aspect | Tapered Roller Bearings (TRBs) | Spherical Roller Bearings (SRBs) |

|---|---|---|

| Design | Conical rollers; inner/outer ring raceways converge at one point | Barrel-shaped rollers; two rows diagonally positioned |

| Load Capacity | Handles both radial and axial loads in one direction | Suited for high radial loads and moderate axial loads |

| Misalignment Tolerance | Sensitive to misalignment, meticulous installation required | Tolerates certain misalignment, compensates for shaft movement |

| Friction and Speed | Higher friction, not ideal for high-speed applications | Lower friction, better suited for higher-speed operations |

| Cost and Maintenance | Lower initial cost, requires precise mounting | Higher initial cost, less maintenance due to self-align feature |

| Applications | Automotive, heavy machinery, industrial gearboxes | Mining, construction, wind turbines, paper mills |

Things to Consider When Choosing Between Tapered Roller Bearing and Spherical Roller Bearing

Here are the key factors to consider when choosing between Tapered Roller Bearings and Spherical Roller Bearings:

| Key Factors to Consider | Tapered Roller Bearings | Spherical Roller Bearings |

|---|---|---|

| Load Conditions | Ideal for high combined loads (radial and axial) in gearboxes, axles, etc. | Best suited for high radial loads with moderate axial loads in wind turbines, heavy machinery, etc. |

| Misalignment Tolerance | Highly sensitive to misalignment, prone to wear from even slight misalignment. | Can accommodate some misalignment due to their design, forgiving in applications with potential shaft movement. |

| Friction and Speed | High friction, limiting suitability for high-speed applications. | Lower friction, better suited for higher-speed applications. |

| Cost and Maintenance | Lower initial cost but require precise mounting, increasing maintenance needs. | Higher initial cost but less maintenance-intensive due to their self-aligning features. |

| Application Specifics | Consider environmental factors and space constraints for bearing size/design. | Consider bearing materials, sealing options, and consult manufacturers’ data for specific load capacity, speed limit, and dimensions. |

| Additional Tips | Consult bearing specialists for demanding applications and prioritize long-term reliability and safety over initial cost. | When unsure, prioritize higher load capacity and misalignment tolerance for critical applications. |

Recommended Reading: Bearing Basic & Overview of Bearing Types: Your Ultimate Guide

In a world where precision meets resilience, choosing between Tapered Roller Bearings and Spherical Roller Bearings is about finding the perfect fit for every rotational challenge. While Tapered Roller Bearings excel in handling combined loads with surgical precision, Spherical Roller Bearings dance elegantly with misalignment, embracing heavy radial loads effortlessly. As you navigate this labyrinth of bearing choices, remember to choose the right bearing manufacturer, who could get you the best bearings and bushes suitable for your needs.

For top-tier performance and reliability, consider Hi-Bond, a leading bearing manufacturing company with a legacy of excellence in crafting hi-tech bearings and bushings.

Elevate your machinery’s efficiency and durability with Hi-Bond‘s top-grade bearing solutions.

Tapered Roller Bearing vs Spherical Roller Bearing FAQs

- What is the difference between spherical roller bearings and tapered roller bearings?

Tapered roller bearings feature conical rollers and are ideal for high combined loads. On the other hand, spherical roller bearings have barrel-shaped rollers, offering versatility with self-alignment and high radial loads.

- What are spherical roller bearings used for?

Spherical roller bearings are commonly used in heavy machinery like mining equipment, construction machinery, wind turbines, and paper mills due to their ability to handle extreme loads and misalignment.

- What is the purpose of taper roller bearing?

Taper roller bearings serve the purpose of handling both axial and radial loads with precision, making them suitable for applications like automotive drivetrains, steering systems, and heavy machinery components.

- What are the differences between tapered roller bearings and spherical roller bearings?

Key differences lie in their design and applications. Tapered bearings excel in combined loads and precision, while spherical bearings accommodate misalignment and excel in handling heavy radial loads.

- What are the features of tapered roller bearings?

Tapered roller bearings offer a high load-carrying capacity, precision, and versatility in handling axial and radial loads. Their trapezoidal tapered rollers ensure efficient load distribution.

- What are the applications of tapered roller bearings?

Tapered roller bearings find applications in automotive components, heavy machinery like construction and mining equipment, and industrial gearboxes due to their durability and load-handling capabilities.

- What is the comparison between Tapered Roller Bearing vs Spherical Roller Bearing?

The comparison revolves around load conditions, misalignment tolerance, friction, speed, cost, and maintenance. Spherical roller bearings excel in misalignment tolerance, while tapered roller bearings offer precision in combined loads.