It’s no secret that friction is one of the biggest enemies of mechanical equipment. Friction causes wear and tear on moving parts, leading to expensive repairs or replacements. That’s why engineers always look for the best bearing manufacturers in town to get the best bearings and bushings to reduce friction.

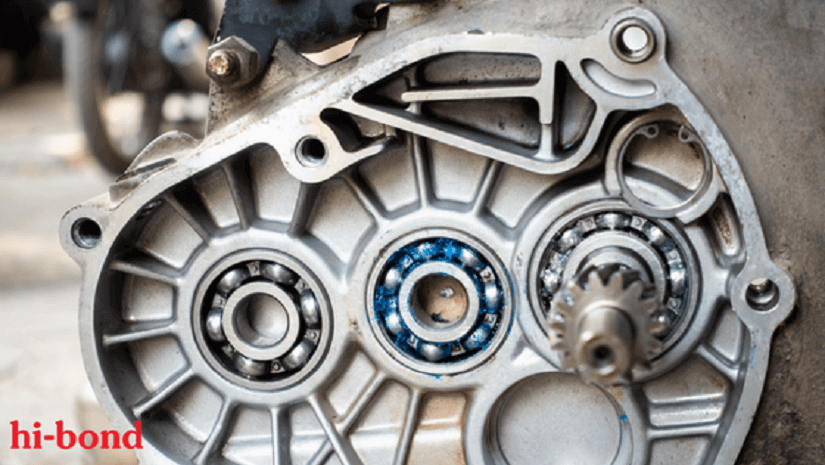

One way to do this is by using ball bearings and bushings. Ball bearings and bushings are small, round balls placed between two moving parts. The balls rotate freely, which reduces friction between the parts. As a result, it helps the equipment run more smoothly and last longer.

So, next time you’re wondering how something works, remember that ball bearings may be helping to reduce friction and keep things running smoothly!

Read More: Difference Between Sleeve Bearings Vs. Ball Bearings

Top 8 ways to use ball bearings and bushings:

- Bearings are used in rotating parts to reduce friction and help the component move smoothly.

- They can be used in conveyor belts to keep the belt moving.

- Bearings can also be used in fans to keep the blades moving smoothly and quietly.

- Ball bearings are often used on wheels, vehicles, and on machinery such as lawnmowers. They help to reduce friction and make it easier for the wheel to turn.

- Many door hinges also use ball bearings to keep the door opening and closing effortlessly.

- Ball bearings are commonly found in skateboards, roller skates, and other similar products. They help to reduce friction and make it easier for users to move around easily.

- Some computer hard drives also use ball bearings to keep the disk spinning smoothly inside the casing.

- Printers typically have several ball bearings that help to keep moving parts aligned correctly so that printing is accurate and reliable every time you print something out.

How Does Ball Bearing Work?

When using something with moving parts, like a machine, it’s important to reduce friction as much as possible. Otherwise, you’re going to wear down those parts faster, and they will need to be replaced more often.

That’s where ball bearings come in. Ball bearings help reduce friction and wear because there’s less contact between the surfaces. In addition, the balls create a cushioning effect, spreading the load over a larger area.

- The bearing is sized as per the load it will carry. Therefore, a larger bearing will carry more load than a smaller bearing and can handle more contact pressure.

- The ball-bearing races are designed to provide enough clearance so that there is no rubbing contact between the inner and outer races of different-sized balls.

- They use lubrication to reduce friction, which is why they are so effective at reducing friction in moving parts.

- They have low rolling resistance, which means that they can easily be used in high-speed applications like gears, ball screws, etc., where there is a need for speed and efficiency.

- In ball bearings, only one end of the shaft rotates. In contrast, the other end remains stationary or moves very slowly – this allows them to provide high torque while still allowing rotation of the shaft on its axis through the use of a helical groove machined into each ball’s outer surface (which allows them to roll freely within their respective race).

To elucidate,

Ball bearings and bushings are designed to spin freely without friction between the races and balls. They do this by using rolling elements in the bearing races, which contain steel balls or rolling surfaces that spin on their axis in relation to each other. The number of rolling elements determines how fast the bearing will rotate and how much frictional resistance there will be between its races and balls.

Moreover, the low coefficient of friction between ball bearings and other surfaces also makes these bearings ideal for use in devices that must operate at high speeds, such as pumps and fans. The lower coefficient means that the device will not wear out as quickly and can run longer before needing to be replaced.

This type of ball bearing also has very little backlash, meaning there is very little slippage between its races and balls when they move against each other at different speeds (with each other). It allows relatively simple mechanisms, such as gears or rotating shafts, to operate smoothly without causing excessive wear or damage.

Here are some of how different parts of a ball bearing helps to lower friction.

-

The Bearing Races

The bearing races are the outermost rings of the ball bearing that provide a smooth running surface to the inner ring. These races help to reduce friction by providing a smooth running surface for the inner ring, which prevents abrasion and wear.

-

The Inner Ring is Stiffer

The inner ring is stiffer than the outer ring and can help to reduce friction by providing more support for a smooth running surface for the outer ring, which helps to reduce wear and tear on both rings.

-

The Spacers are Lubricated

Spacers are used to separate different types of balls to reduce friction between them, and they also help to provide better lubrication between different types of balls as well as keeping them apart during operation so that they don’t rub against each other or themselves when moving around inside of a bearing housing or cage assembly.

All of this adds to a longer life for your machines and less money spent on replacements and repairs.

Does Ball Bearing Help to Reduce Friction Forces at Rest, as well as to turn?

Rolling contact between the bearing and its housing is eliminated in roller bearings, reducing frictional resistance. In some cases, ball bearings can even eliminate rolling contact between the shaft and hub of a transmission shaft or propeller shaft.

In cylindrical roller bearings, rolling contact between the bearing and its housing is eliminated, which reduces frictional resistance. In some cases, ball bearings can even eliminate rolling contact between the shaft and hub of a transmission shaft or propeller shaft.

Ball bearings are designed to be used with high loads (thrust) and low loads (torque). Therefore, when used in high-pressure applications such as hot water heating systems or hydraulic systems for heavy equipment, they must withstand higher loads than when used in low-pressure applications such as air conditioning units or compressors for refrigeration systems.

Recommended Reading: Three Life-Changing Environments for Bearings

How to Get the Most Out of Your Ball Bearings?

- Keep them clean – Ball bearings last longer and perform more smoothly when they are clean.

- Inspect them regularly – Check for signs of wear and tear, and ensure that the bearings are properly lubricated.

- Use them for the right applications – Avoid using ball bearings for heavy loads or high speeds.

- Store them properly – Store ball bearings in a dry, dust-free environment.

- Don’t over-lubricate them – Too much lubricant can cause ball bearings to fail prematurely.

- Keep them shielded – Shielded ball bearings are better protected from dirt and debris.

- Avoid using damaged bearings – Damaged ball bearings can cause accidents and injuries.

- Use the right size bearing – Make sure the ball bearing is the correct size for the application.

- Check the load rating – Make sure the ball bearing you’re using can handle the load it will be subjected to.

- Follow the manufacturer’s instructions – Be sure to follow the manufacturer’s instructions when installing and using ball bearings.

Find the Best Bearings and Bushes Suppliers Near You

Well, that’s all there is to it. Understanding the concept behind ball bearings has led to many applications and developments in technology and science. Ball bearings are used in virtually any situation where there is contact between two surfaces that need to spin. So it includes engines, like cars and airplanes, amongst other things.

At Hi-bond bearings Pvt Ltd, one of the top-notch bearing manufacturing companies in Gujarat, we provide best-in-class bearing and bushings for myriad applications. If you have any additional questions or thoughts, please feel free to comment below.