A Reliable Solution for Industrial Applications.

Bronze sleeve bearings, also known as bronze bearings, have grown in popularity in a variety of industrial applications due to their remarkable durability, corrosion resistance, and adaptability. These bearings can endure heavy loads, high speeds, and severe environments, making them a solid choice for machinery and equipment producers.

In this blog, we will delve into the unique characteristics of bronze sleeve bearings, examine the factors that determine their strength and durability, and provide critical considerations when selecting the appropriate bearings for specific requirements.

Understanding Bronze Sleeve Bearings

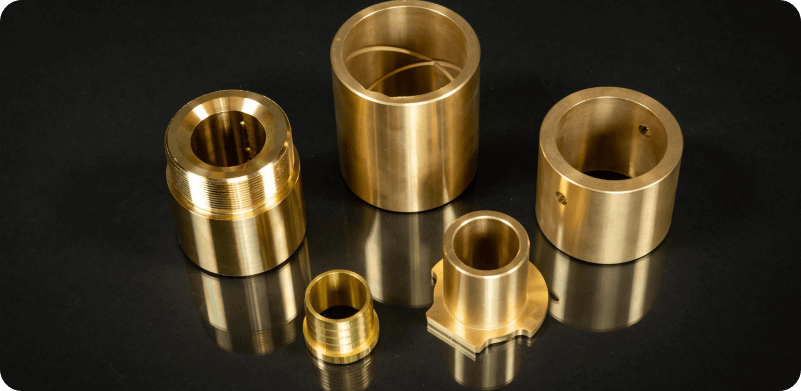

Bronze sleeve bearings, a type of plain bearing, consist of a cylindrical piece of bronze that supports and guides rotating shafts or other moving parts. The bearing surface typically comprises a soft, porous bronze material impregnated with lubricating oil, which reduces friction and wear.

-

The Composition and Construction of Bronze Sleeve Bearings

Bronze sleeve bearings are often made of bronze alloys, which include copper as the principal constituent as well as different proportions of other metals like tin, zinc, and lead. These alloys can be tailored to optimize material qualities such as load-bearing capacity and corrosion resistance for specific applications. The production procedure includes precisely cutting the bronze material and developing a porous structure for oil retention.

-

Lubrication Needs of Bronze Sleeve Bearings

Bronze sleeve bearings are self-lubricating in nature. The porous structure of the bronze substance allows lubricating oil to be retained and distributed, reducing friction and wear. However, additional external lubrication may be required in some applications with harsh conditions or greater speeds to ensure optimal performance and lifetime.

Read More: Why do You Need Bronze Sleeve Bearing?

Benefits of Bronze Bearings in Industrial Applications

-

Wear Resistance and Durability

Bronze is a tough material that can sustain high loads and speeds. The porous structure of bronze sleeve bearings allows for oil retention, which improves wear resistance and ensures a longer service life.

-

Corrosion Protection

Bronze sleeve bearings have good corrosion resistance, making them suited for applications involving dampness or chemicals. This property enables them to operate consistently in severe conditions without succumbing to corrosion-related failures.

-

Machinability and Adaptability

Bronze bearings are available in various compositions and forms, allowing for versatility in different industrial applications. Depending on the specific requirements of an application, different bronze alloys can be selected to optimize performance. Bronze bearings can be manufactured as solid bushings, flanged bushings, thrust washers, or other forms, providing flexibility in design and installation.

-

Thermal Conductivity

Bronze has good thermal conductivity properties, which means it can effectively dissipate heat generated during operation. This is particularly advantageous in high-speed applications or situations where heat buildup can be a concern. Efficient heat transfer helps in maintaining optimal operating temperatures, preventing overheating and potential damage to the bearing and surrounding components.

-

Cost-Effectiveness

Bronze bearings offer a cost-effective solution for many industrial applications. Compared to other types of bearings, bronze bearings are often more affordable, especially when considering their durability and long service life. The self-lubricating properties of bronze bearings also contribute to cost savings by reducing the need for frequent lubrication and associated maintenance.

Recommended Reading: Understanding Uses: Bronze, Brass & Copper in Manufacturing Industries

Factors Influencing the Strength and Durability of Bronze Sleeve Bearings

-

Material Properties and Alloy Composition

The composition of the bronze alloy used to make bronze sleeve bearings has a big impact on their strength and longevity. Different alloy compositions can be customized to optimize features like load-bearing capacity and corrosion resistance.

-

Porosity and the Ability to Self-Lubricate

The ability of the bearing material to hold and distribute lubricating oil is affected by its porosity. Increased porosity improves the self-lubricating properties of bronze sleeve bearings, lowering friction and wear.

-

Performance and Surface Finish

The surface finish of bronze sleeve bearings is extremely important to their performance and durability. A smooth surface lowers friction and wear, allowing for more efficient operation and service life.

-

Environmental and Operating Conditions

The operating conditions of bronze sleeve bearings determine their strength and durability. Load, speed, temperature, and exposure to corrosive or abrasive substances all have an impact on its performance and longevity. Bearings that are designed and produced to withstand specific operating conditions have higher durability and longer service life.

-

Manufacturing Techniques and Quality

The strength and longevity of bronze sleeve bearings are affected by the manufacturing technique used. Proper machining and finishing procedures ensure that the bearings are defect-free and of constant quality, improving their performance and reliability.

Considerations for Choosing the Right Bearings

Cost Considerations in Bearing Selection

The cost of bearings might vary based on the material used. Bronze bearings are often less expensive than stainless steel or ceramic bearings due to cheaper raw material costs and less sophisticated manufacturing procedures.

Durability and Performance Characteristics

When choosing bearings, it is critical to examine their performance and longevity. Understanding the application’s unique requirements and selecting bearings with sufficient load-bearing capacity, wear resistance, and corrosion resistance provides dependable and long-lasting performance.

Application Specific Requirements

Different applications may have specific requirements that must be taken into account while selecting bronze sleeve bearings. To ensure that the bearings are well-suited, factors such as operating temperatures, loads, speeds, and environmental conditions should be assessed.

Size, Tolerances, and Surface Finishes

The size, tolerances, and surface finishes of bearings must align with the requirements of the machinery or equipment. Precise dimensions, appropriate tolerances, and suitable surface finishes ensure optimal fit and performance.

Quantity and Ordering Considerations

When ordering bronze sleeve bearings, factors such as required quantities, lead times, and supplier capabilities should be taken into account. Efficient inventory management and reliable suppliers contribute to uninterrupted operations.

Choose the Right Bearing Manufacturer

Bronze bearings offer numerous advantages in industrial applications. As a top bearing manufacturing company, Hi-bond Bearings Pvt. Ltd recognizes the importance of providing high-quality bronze bushes, bronze sleeves, and linear sleeve bearings to meet the diverse needs of their customers. The exceptional characteristics of bronze, such as high strength, excellent corrosion resistance, and self-lubricating properties, make it an ideal choice for demanding industrial environments.

Conclusion:

So, whether it’s reducing friction, increasing load capacity, or enhancing durability, bronze bearings from Hi-bond are tailored to meet specific requirements. Trust in Hi-bond‘s expertise and choose the right bronze sleeve bearing to optimize performance and reliability in your industrial operations.

Contact Hi-bond today to find the perfect solution for your tailored requirements.

FAQs:

Q1. Why is bronze a good bearing material?

Bronze is a good bearing material due to its durability, wear resistance, corrosion resistance, and self-lubricating properties. It can withstand heavy loads and high speeds, making it suitable for industrial applications.

Q2. Do bronze bearings need lubrication?

Bronze sleeve bearings have self-lubricating properties due to their porous structure, which retains and distributes lubricating oil. In most cases, additional lubrication may not be necessary. However, in extreme conditions or high-speed applications, external lubrication may be required.

Q3. What are sleeve bearings usually made of: stainless steel, bronze, aluminum, or cast iron?

Sleeve bearings can be made from various materials, including stainless steel, bronze, aluminum, and cast iron. The choice of material depends on the specific application requirements, considering factors such as load, speed, environmental conditions, and cost. Bronze is a popular choice due to its excellent combination of properties and cost-effectiveness.

By providing comprehensive information about bronze sleeve bearings, addressing frequently asked questions, and highlighting their advantages, we aim to assist engineers, machinery manufacturers, and industry professionals in making informed decisions when selecting bearings and minimizing the risk of premature failures or costly downtime.