A perfect bearings product in the wrong market leads to failure. For this, should we blame the product or the market? The answer is neither. We need to rectify the product-market fit.

However, in businesses, it is simpler to blame the product for being inefficient. Or to blame the market for not recognizing true potential.

Solving the root problem of proper product-market fit is ideal, but also a tedious task.

Similarly, in any industry with machinery, there is a scapegoat. And interestingly, very few machinery can work without them.

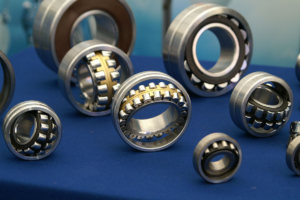

They are the bearings — the backbone of the entire manufacturing industry.

In this blog we will see in detail where things can go wrong when choosing or installing a bearing.

-

Wrong fit

Bearings are generally blamed for their short life in certain machinery. The common cause of this is when bearings are not provided with the right fit.

Bearings and bushes suppliers manufacture certain sizes which are the norm in the industry. These bearings work ideally under a specified fit. If this fit is not facilitated by machines, they require customized bearings.

Both the shafts and the housing need to be tailored to the right tolerance levels to achieve the right fit. Likewise, if the load is heavy or if the volume is high, a tight fit is needed to capacitate the same.

When a tighter fit is required, the shaft and housing tolerances need to be checked against the internal clearance of the bearing.

If the internal clearance isn’t of the right dimensions, the bearing might fail. This failure is because of the inability to rotate under that particular fit.

-

Opting for the wrong type of bearings

The diversity in bearings is unrivaled. Though ball, plain, and roller bearings are the major types, there are several others.

- Cylindrical roller bearing,

- Tapered bearing,

- Thrust bearing,

- Deep groove ball bearing,

- Magnetic bearing,

- Self-aligning ball bearing

These are only a few of the several bearing types available. Each of them is designed for specific purposes. Also, each type has different load and volume capacities.

Many buyers visit a bearing manufacturing company, choose the least expensive one, and order them. This might be economical on that date. From the high potential of failure to replacement costs, this is a sure-shot way of burning a hole in the pocket.

Choosing the right type is important and failure to do so shall often result in bearing failure.

-

Improper shaft and housing tolerances

Bearing manufacturers use implements to check the accuracy of bearing dimensions to the T. On the contrary, shaft and housing manufacturers fail to reach the same levels of accuracy.

This variation in measurements affects the bearing performance. How? The tolerance levels control the roundness of the shaft and the housing. If the bearing is used with an out-of-shape shaft or housing, the bearing performance deteriorates.

Therefore, when the bearing fails, look into other factors before blaming the bearing. Factors like shaft and housing dimensions, material, and vibration levels need to be checked.

-

Inadequate bearing support

The housing shoulder must fully support the bearing and its rollers. Failure of any extent to support the roller is going to be disastrous. It reduces the bearing’s loading capacity by a fair margin. Also, premature damage is common with inadequate bearing support.

Consulting with the bearing manufacturers for the ideal surface and operating conditions is a must.

Simple actions include ensuring the support surface is flat to avoid soft foot. A soft foot condition furthers the internal misalignment of the machine. This further adds unwanted load onto the bearings. Also, bending of shafts is common when the misalignment is excessive.

Also, make sure the housing support surface is rigid enough to avoid flexing.

Corrosion may also deteriorate the support for bearings. The bearing rings need even support, and due to fretting corrosion, the support fails.

When there is no adequate support, distortion in the load zone is common. This distortion furthers into causing premature spalling.

Inadequate support or improper mounting may be reasons for bearing failure. So, keeping an eye out for these and rectifying them shall increase the bearings’ life.

-

Lack of maintenance

A common nemesis to bearings’ life is the lack of maintenance. Operating with a damaged or a corroded bearing is a recipe for disaster. To eliminate the chances, sincere maintenance at regular intervals is the key.

- Insufficient lubrication

- Use of improper lubricants

- Inadequate lubricant viscosity

These are the usual mistakes committed during regular maintenance. And working these out shall keep the bearings in good stead.

Conclusion:

The last thing bearings and bushings suppliers need to listen to is that their bearings have failed. Ensure the above points are noted and rectified before blaming the failure on the bearings.

And if the bearings genuinely fail, replace them before it is too late.

For more information regarding bearings and everything around it, Hi-Bond is your destination.