Bushing bearings are essential components in achieving smooth and precise linear motion. Since their patent, linear ball bushings have been commercially available to achieve precise linear motion. Designers now have the option to choose between the accuracy of rail guides or the cost-effective nature of linear ball bushings.

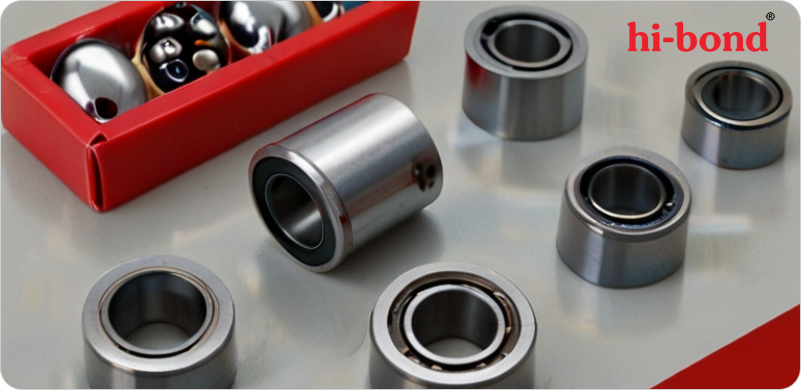

Over the years, linear ball bushing bearings have greatly improved by increasing load capacities and including a self-alignment feature. These advancements have given manufacturers various reasons to specify either option for their applications. Bearing manufacturers like Hi-bond Bearings Pvt. Ltd. offer ball bushings, a cost-effective solution for achieving linear motion in industrial machinery, robotics, and mechanical systems.

Ball bushings minimize friction, operate smoothly and accurately, and provide control, self-alignment, long-lasting performance, and exceptional value. In this blog post, the experts will explain why using ball bushing bearings is the right choice for your linear motion systems.

An Overview of Ball Bushing Bearings

Ball bushing bearings (a type of linear bearing) are engineered with a cylindrical outer shell housing tiny balls that enable smooth and precise linear movement. These bearings and bushings contain a cylindrical outer shell containing recirculating balls, allowing them to glide effortlessly along an inner race. Their purpose is to support both radial and axial loads, minimizing wear and extending the service life of machinery.

Many series of ball bushing bearings have proved themselves to be reliable industry standards due to their exceptional qualities.

- Super Series: Widely recognized for their exceptional self-aligning capabilities, the super series bearings optimize performance across various applications. They can accommodate slight misalignments without compromising movement precision, ensuring reliable and precise functionality.

- Classic Series: The classic series is highly regarded for its impeccable durability. These bearings feature robust construction, making them suitable for heavy-load applications while maintaining smooth and consistent linear motion.

- Precision Steel Series: With a focus on high load carrying capability, the precision steel series is designed with a user-friendly approach. These bearings facilitate easy installation and replacement, providing maintenance engineers with added convenience.

Material Composition: Ball bushing bearings are commonly crafted from high-quality bearing steel or, in some cases, aluminum for the housing. These materials are carefully selected for their strength and compatibility with the balls. Speaking of balls, they are often made from hardened steel or ceramics, particularly in demanding applications. It ensures reduced weight without compromising overall performance.

The Structure of Linear Ball Bushing Bearings

Linear ball bushing bearings consist of various types, each with a specific structure to meet different application needs.

- The SM type includes an outer cylinder, side ring, retainer, and ball element.

- The SMF type features a flanged outer cylinder along with these components.

- The GM type comprises a steel outer cylinder, a resin outer cylinder, ball elements, and a resin seal.

It is important to note that the GM type has a resin outer cylinder, the SM type has a steel outer cylinder, and the SMF type has a steel outer cylinder with a flange. Understanding these basic structures can help select the appropriate linear ball bushing bearing from the bearing manufacturing company for the desired application.

The Benefits of Resin Material for Bushing Bodies

Resin material offers multiple advantages when used in the construction of linear ball bushings. One key benefit is its ability to reduce the weight of the bushing by approximately 50% weight reduction compared to traditional steel versions.

Further, resin material can also be used for the ball return, contributing to weight reduction. Another advantage of using resin is the reduction in operational noise. Considering the cost-effectiveness and expanded application possibilities, opting for resin-based linear ball bushing bearings can be a wise choice.

Improved Load Capacity, Durability, and Cost Savings

Linear ball bushings are designed to provide improved load capacity, longer service life, and reduced material costs. Their design characteristics also reduce installation time, resulting in increased cost savings. Energy savings during operation can also be achieved by using linear ball bushings.

Smooth and Quiet Operation

Using resin material in linear ball bushings enhances their smooth operation and contributes to noise reduction. This effect is particularly noticeable when the ball retainer is also made from resin material. Internal play is controlled by specifying higher tolerance versions, ensuring ball bearings use low friction and smooth operation.

Flexibility in Design and Self-Aligning Capability

One major advantage of linear ball bushing bearings is their self-aligning feature. Unlike profiled rails that require precise alignment, ball bushings can rotate on the shaft and compensate for shaft misalignment. This design flexibility makes ball bushings suitable for applications where mating components may have lower precision.

Self-aligning linear ball bushings can accommodate misalignment tolerances of up to ±0.5 degrees, compensating for mounting surface inaccuracies, alignment issues, or shaft deflection. This feature ensures an even distribution of the load along the entire length of the bushing, preventing pressure between the bushing’s end edge and the shaft, resulting in low friction and smooth operation.

Effective Sealing

Seals play a key role in preventing the ingress of contaminants in many applications. However, when the ball bushing is self-aligning or tilting, traditional seals may lose contact with the shaft and become ineffective. To overcome this issue, bearing manufacturers offer floating seals that maintain constant pressure for effective sealing. Floating seals are also effective in reducing friction commonly found in conventional seals.

Broad Range of Applications

Linear bushing bearings find applications in transportation equipment, food processing equipment, semiconductor manufacturing equipment, industrial robotics, and a broad range of industrial, commercial, and scientific systems that require precise and smooth motion. Their versatility makes them suitable for numerous applications.

The Versatility of Linear Ball Bushing Bearings in Their Applications

Linear ball bushing bearings find extensive use across various industries due to their exceptional performance and reliability. Here are some of the key applications where these bearings shine:

Automation and Robotics: The precise and fluid motion provided by ball bushing bearings is indispensable in the automation and robotics industry. Models like the super smart ball bushing bearings exemplify this quality. These bearings enable smooth and accurate motion in robotic arms, ensuring precise positioning with minimal friction. It is important for delicate automated tasks that require precision and reliability.

Material Handling Systems: Ball bushing bearings play a fundamental role in material handling systems, especially in conveyor belts and linear actuators. Their rugged design allows them to withstand the high-duty cycles and variable loads encountered in material transport. By providing reliability and longevity to essential logistics equipment, these bearings contribute to the smooth and efficient operation of material handling systems.

Transport and Packaging Equipment: The rapid and dependable operation of transport and packaging machinery can often be attributed to ball bushing bearings. These bearings ensure a seamless transition of goods, minimizing downtime and maximizing productivity. With their robust construction and ability to maintain smooth linear motion under continuous use, ball bushing bearings are a trusted choice in the transport and packaging industry.

Aerospace and Defense: In the demanding fields of aerospace and defense, ball bushing bearings must meet strict performance and precision requirements. High-spec bearings are often employed in this sector, providing the necessary precision and load capacity for sensitive applications within aircraft systems or military hardware. Their reliability and durability make them an essential component in this critical industry.

Medical Devices: A ball bearing benefits the medical industry with exceptional precision and low friction. They are used in medical devices such as MRI machines and precision lab equipment. Their non-magnetic and corrosion-resistant properties make them ideal for sterile and sensitive medical environments. By ensuring accurate and smooth motion, ball bushing bearings contribute to precise diagnostics and treatments in the medical field.

Top Advantages of Linear Ball Bushing Bearings

Linear ball bushing bearings offer advantages that make them a preferred choice in various applications. Their special internal ball recirculation system reduces friction, resulting in smoother and longer-lasting performance. Their design also allows for some misalignment, making them more tolerant and easier to use than other linear bearings.

Strong and Reliable for Heavy Loads

Ball bushing bearings excel at handling heavy loads while maintaining smooth and consistent motion. The super smart series is specifically designed to handle substantial loads, making it ideal for industrial machinery that requires reliability over long periods of operation.

Precise and Accurate Motion

Linear ball bushing bearings, such as the precision steel series, offer precise and accurate motion. This level of precision is crucial for applications like 3D printing, CNC machinery, and other equipment that rely on exact movements for optimal performance.

Less Friction, More Efficiency

Thanks to their rolling elements, ball bushing bearings have reduced friction compared to plain bearings. These ball bearings and bushings enable smoother movement of parts and components, resulting in improved efficiency and lower energy consumption.

Fast and Reliable for Rapid Motion

Linear ball bushing bearings can maintain high speeds without generating excessive heat. This makes them well-suited for applications that require fast motion, such as high-speed automation tasks, where they can deliver reliable performance without compromising speed.

Easy Alignment for Hassle-Free Operation

Misalignment can be a challenge in linear motion systems, leading to uneven wear and potential failures. However, self-aligning ball bushing bearings, like the adjustable bearings in the super smart series, can compensate for misalignment, ensuring smooth operation and extending the lifespan of the bearing and the machine.

Low Maintenance for Ease of Use

Many ball bushing bearings are designed to be self-lubricating, reducing the need for frequent maintenance. This feature, found in options like the ball bushing bearings, makes them particularly suitable for environments where maintenance is difficult or could cause significant downtime.

Thus, linear ball bushing bearings sourced from a reliable bearing manufacturing company continue to be a preferred choice across various industries due to their powerful performance, reliability, and efficiency in an expansive range of applications.

Satisfy Your Application Needs of Linear Motion with Bearings and Bushings at Hi-bond!

Linear ball bushings, or ball bushing bearings, are reliable for linear motion guidance when mounted on a round shaft. These self-aligning bearings operate with low friction, making them a cost-effective and efficient option for various linear motion applications.

If you’re in need of high-quality bearings and bushings to improve your linear motion experience, discuss them with Hi-bond Bearings Pvt. Ltd. As trusted bearings and bushes suppliers with a diverse inventory, they can provide expert guidance and help you reap the benefits of bearings suitable for smooth and efficient linear motion in your applications.