Imagine a world without any machinery. Daunting, ain’t it? Similarly, the manufacturing sector without bearings and bushings is unimaginable. Though every part of the machine has its role to play, these two are of paramount importance. Even if one goes off, the whole machinery is rendered useless and needs absolute fixing.

No matter how insignificant it may seem, the bushing is one of the most important parts of machinery. Bushing comes up wherever there is a need for a connection between two parts. As much as the component’s utility itself is important, there is one thing that is of equal importance. It is the appropriate installation of bushings that is important for its smooth functioning.

Here we will see what exactly bushings are and how to install and remove them efficiently.

What is Bushing?

A bushing, commonly called plain bearings, sliding bearings, or sleeve bearings is an element within machinery used to reduce friction. They are tube or sleeve-like items which play a pivotal role in minimizing noise and vibration in machinery.

The bushing is a specific type of bearing equipment where bearings form an umbrella under bushings are one of their kind. It is the most simple form of bearing which comprises a shaft rotating in a hole. It is the least expensive out of all bearings. Being lightweight and compact are some of its prominent features.

It is predominantly made up of three parts, an outer shell, an elastomer (rubber), and the third, the inner sleeve. The synthetic rubber facilitates movement between two different components.

Though no bearings and bushing suppliers vouch for this, it is advisable to view bushing as a specialized type of bearing, then a separate component.

What is it made up of?

Any bearing manufacturing company makes bushings in various materials like plastic, cast iron, bronze, or steel. The kind of bushing material matters and depends upon the purpose of use of the part. It has no rolling items within the bushing unlike few other kinds of bearings.

In what all industries are bushings used?

In crucial industries where the error rates are close to negligible, bushings become an indispensable pick. Their indefinite running capabilities create a lot of demand in such industries. For example, power plants, steam turbines, and turbomachines. Bushings have heavy load capacity, so it is a choice of industries like construction, and mining as well.

As it can even run when it’s dry without any friction, bearing manufacturers supply them to the food industry as well because lubricants are kept away from food.

What are the different Bushings?

There are three types of bushings–solid, split, and clenched.

Solid bushings are well-rounded throughout their diameter. Whereas, split bushings, as the name suggests, have a slit across their length. Clenched bushings are like split bushings but with a clench at their slits.

There are two more kinds of bushings based on their material.

Hardened steel bushings– They are heavy bushings ideal for low speeds but heavy loads.

Polymer bushings- They work well for high speeds but can come in handy for fast oscillations and rotation applications.

Apart from these, there are a wide variety of bushings available in the market. Finding a retail shop and asking for a bushing is not how they are meant to be invested in.

Consulting with bearings and bushes suppliers, communicating your requirements is how one should invest.

Factors based on which a kind of bushing is selected?

PV or Pressure-Velocity factor is very important while choosing a bushing.

When two mating components run, some thermal energy is produced. This energy is directly proportional to the pressure, sliding velocity of the components, and friction.

All kinds of bushings have their PV factor. It is necessary to consider it while opting for a bushing to use in your particular set of operations.

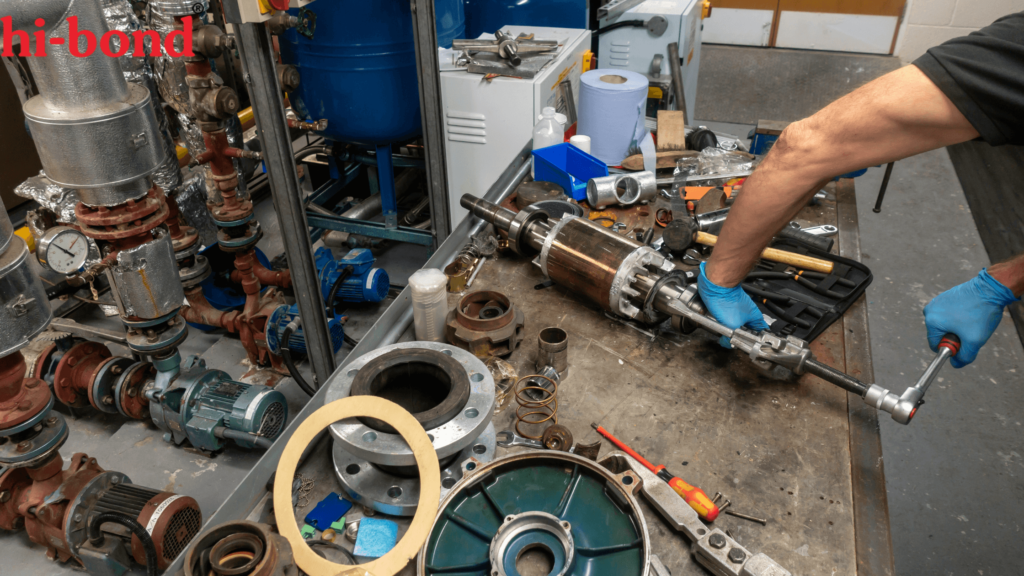

Installation and Removal Process of Bushings:

Mechanical:

To install bushings, we need an appropriate size installer and components with some lubrication. Metal expansion due to the heat generated because of friction. This is something to consider while deciding the size as well.

Tools: Hammer and Hydraulic press

Using a hammer is the most basic way to install a bushing. Just make sure all components like the shaft and rubber rings along with bushing are in place and hit. But this can cause damage to the parts.

So you can use Hydraulic Press, a machine that applies full force to fix the bushings.

First align the workpiece, bearing, and shaft.

Lower the press slowly and observe where the force is being applied.

It needs care and proper instructions while handling too but is much easier.

Right measurement is essential for a proper installation using measuring tools like a micrometer. Improper installation can cause breakage which can cancel out the entire purpose of reducing friction.

Thermal Installation and Removal of Bushings:

Another method of installing and removing bushings is by altering the temperature of the bushing.

Lowering or raising the temperature of the components within limits with caution can serve the purpose. The safety procedures followed for mechanical methods apply here too.

If sizes are not within the recommended tolerances, one should replace the parts.

But before that ensure that all the tools, as well as the mating parts, are clean with no dust, grease, or any similar particles clinging to the components. Such foreign particles hamper the working of the machinery.

Conclusion:

Bushing increases responsiveness. For machinery to work smoothly, it is a must to follow a laid down procedure given by the bearing and bushes suppliers. Exercise caution while both installing and removing for proper functioning. Else more than breakage, it can lead to injuries as well.

With this guide, one can install and remove bushings safely. What next? Invest in the best bushings made by Hi-bond and install them. Being an industry leader in manufacturing bushings and bearings, Hi-bond is where your requirements are met in absolute.

High-quality bushings at competitive prices are guaranteed with Hi-bond.