Introduction

If you work with machinery, it’s important to understand how bearings work and why they matter. Bearings don’t just help machines run better; they extend their lifespan and improve overall performance. These small but powerful components reduce friction and support the movement of different parts, ensuring everything runs smoothly and effectively.

Because bearings play a crucial role, choosing the right industrial bearing supplier is essential. The right bearing manufacturing company can keep your equipment running reliably, save you time, cut down on repair costs, and prevent unnecessary downtime. With so many suppliers it’s easy to feel overwhelmed. But finding a trusted supplier who offers quality products, expert support, and helpful advice can make all the difference.

In this guide, we’ll cover the basics of how industrial bearings work, the different types available, their main benefits, and most importantly, how to choose the right industrial bearing supplier to meet your needs.

Understanding Industrial Bearings

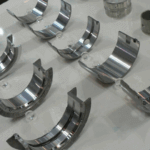

Bearings are often the unsung heroes inside all kinds of machinery. They come in all shapes and sizes, depending on where and how they’re used. They are usually made from tough materials like steel or ceramic, built to handle different loads, speeds, and working conditions. Their job may seem simple — to reduce friction between moving parts but the difference they make is huge.

Bearings are important for the health of your equipment as:

- They help machines run smoother, last longer, and perform better.

- They support important moving parts like shafts, axles, and other rotating elements, ensuring everything moves the way it should.

- They create a smooth surface for parts to roll or slide over each other, reducing friction and wear.

- They also lower the risk of unexpected breakdowns and help you save money on repairs and replacements.

Without good-quality bearings, machines would wear out much faster, operate less efficiently, and cost you massive in the long run. Therefore, it is important to choose dependable bearings and bushes suppliers for high-quality bearings to keep your machines running efficiently and reliably for years.

Different Types of Industrial Bearings

Before choosing a supplier, it’s good to know that there are different types of bearings, each built for a specific purpose:

Ball Bearings

Ball bearings are the most common type, from electric motors to roller skates. They are designed to minimize rotational friction and support radial (side-to-side) and axial (up-and-down) loads. Their reduced contact area between the balls and the raceway lowers friction, decreases wear, and enables smooth, high-speed movement.

Easy to install and requiring minimal maintenance, ball bearings offer a reliable, hassle-free solution for a wide range of moderate-load applications.

Roller Bearings

Roller bearings handle much heavier loads than ball bearings. Instead of balls, they use cylindrical rollers that spread the load over a larger contact area, reducing stress and improving load distribution. This design not only increases strength but also extends the bearing’s lifespan.

Because of their durability, roller bearings are ideal for heavy radial loads and slower speeds. They’re commonly used in conveyor belts, lathes, and heavy industrial machinery — making them the go-to choice for tough, demanding environments where reliability is key.

Needle Bearings

Needle bearings are special roller bearings with thin, elongated rollers that fit into tight spaces. Their slim design increases surface contact, boosting load-carrying capacity and making them ideal for handling high radial loads.

They are perfect for compact machinery like automotive transmissions, motorcycles, compressors, pumps, and textile equipment. Needle bearings come in two types — with or without an inner ring — offering flexibility where minimal clearance between the housing and axle is needed.

Thrust Bearings

Thrust bearings support forces moving along the shaft’s axis rather than from the sides. They are perfect for handling heavy axial (straight-line) loads in applications like automotive systems and rotating machinery. By managing pressure in one main direction, thrust bearings help machines run smoothly and stay protected from damage and excess wear.

Tips for Choosing the Right Industrial Bearing Supplier

Wide Range of Options

A reliable industrial bearing supplier should offer a variety of types, brands, and sizes, all ready to ship. This ensures you find the perfect fit for your machinery without the hassle of dealing with multiple suppliers. The supplier should also provide bearings that meet your machine’s specific load requirements—whether radial, thrust, or combined loads.

Choosing a supplier with a well-stocked selection helps avoid faster wear, breakdowns, and costly repairs, keeping your equipment running smoothly and minimizing downtime.

Fast and Reliable Delivery

When it comes to bearings, fast and dependable delivery can make all the difference. Sometimes, replacing a bearing becomes urgent — and waiting too long could mean costly downtime for your operations. That’s why it’s important to choose a supplier who can deliver within 1–3 working days.

Quick delivery is a good sign that you’ll get the parts when needed, avoiding unnecessary delays and keeping your manufacturing processes running smoothly.

Product Quality

When choosing an industrial-bearing supplier, product quality should be at the top of your list. High-quality bearings perform better, last longer, and save you money by reducing the need for frequent repairs and replacements. Always look for suppliers who offer bearings from trusted and well-known brands — a strong sign that you’re getting reliable products built to last.

Start by checking customer reviews, both on the supplier’s website and on independent review sites. Positive feedback from other buyers is a good indicator of dependable products. You can also look for industry certifications, awards, or memberships, as these often reflect a supplier’s commitment to quality and industry standards.

Technical Knowledge

A great bearing supplier isn’t just there to sell you products — they should be your go-to expert when you need advice. A good supplier knows bearings inside and out and can guide you toward the right choice based on your machine’s needs.

Look for signs of their expertise, like informative blogs, technical resources, qualifications, and awards. These show that the supplier isn’t just moving inventory; they’re committed to helping you solve problems and keep your equipment running smoothly. Having access to real technical support can make all the difference when you’re facing urgent or complex machinery issues.

Reliable Customer Service

Good customer service is just as important as the quality of the bearings you buy. A dependable supplier should be easy to reach, quick to respond, and ready to help — whether answering questions, fixing delivery issues, offering troubleshooting and installation advice, or advising bearing replacement.

Support shouldn’t stop after purchase; strong, ongoing service ensures you avoid downtime and stress, solve problems quickly, and keep your operations running smoothly.

Fair Pricing

While cost is important, the cheapest option isn’t always the best. Focus on suppliers offering fair prices for high-quality, genuine bearings. Quality bearings save you money in the long run by lasting longer and minimizing downtime.

When comparing suppliers, consider the total cost of ownership. Low-cost bearings that fail quickly can lead to higher long-term expenses due to frequent replacements and production stoppages. Look for value, like bulk pricing discounts, but be cautious—if a deal seems too good to be true, it likely is. Counterfeit bearings are a risk, so always research the supplier before purchasing.

Why Choose a Reliable Supplier: Hi-Bond Bearings Pvt. Ltd.

Choosing a trusted supplier like Hi-Bond Bearings offers several key benefits:

- Enhanced Durability & Performance: We provide bearings made from high-quality materials, ensuring long-lasting durability and efficient machinery operation.

- Expert Support: Our team offers technical advice to help you select the right bearings for your specific machinery needs.

- Fast, Reliable Delivery: We ensure quick and dependable delivery worldwide, ensuring our customers receive their products exactly when needed.

- Cost Savings: By offering precision-engineered bearings, we help reduce maintenance costs and extend the lifespan of your equipment.

Extend the Lifespan of Your Machinery by Choosing Industrial Bearings from a Reputable Bearing Manufacturing Company

Bearings may be small, but they are crucial in keeping your machinery running smoothly. Choosing the right industrial-bearing supplier ensures reliability, performance, and peace of mind.

When selecting a supplier, focus on product quality, expert advice, great customer service, and fair pricing. Take your time to ask questions and work with someone you trust — it will pay off in the long run. Consider factors like load capacity, working conditions, speed ratings, accuracy, lubrication, and customization potential.

A reputable supplier like Hi-Bond Bearings offers high-quality bearings that enhance the performance and longevity of your machinery. Visit our website to explore our wide range of bearing products.