Introduction

Let’s be honest, journal bearings don’t get much attention. They’re not flashy. You don’t see them in ads or hear people talking about them at trade shows. But here’s the thing: they’re essential to the smooth operation of countless machines.

Whether it’s the engine in your car, a massive industrial press, or a high-speed turbine powering a plant, journal bearing quietly keeps things moving. They support spinning shafts, reduce friction, and carry heavy loads, all without making a fuss.

But here’s the catch: they only work well when they’re made with serious precision. That’s where machining comes in.

This blog aims to shed light on how Journal bearing the most underrated components are designed, shaped, and perfected. Whether you’re someone who works with machinery or you’re just curious about how things keep running smoothly behind the scenes, you’re in the right place.

What is Journal Bearing?

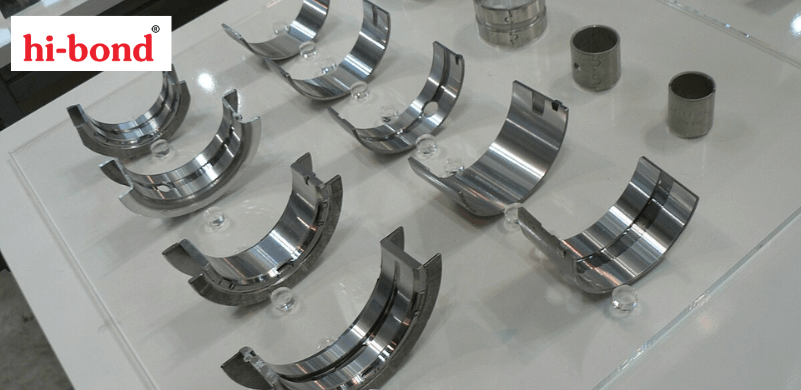

A journal bearing might seem like a simple part, but it plays a crucial role in enabling machines to run smoothly.

Unlike ball or roller bearings, which use a few moving parts, a journal bearing is much simpler. No balls, no rollers, just a smooth, curved surface inside a sleeve that supports a spinning shaft.

So, how does it work?

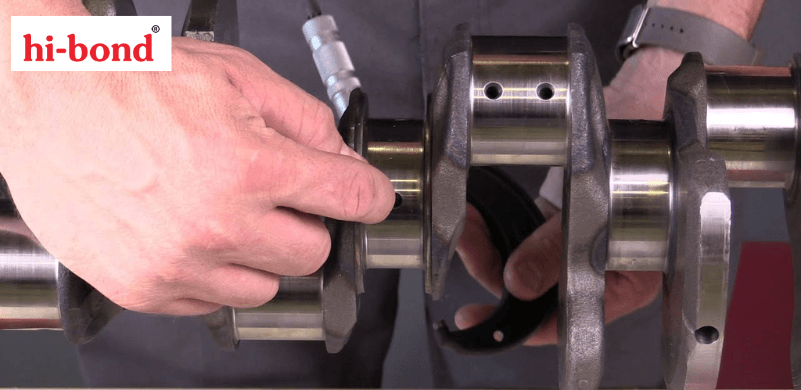

As the shaft turns, a thin layer of lubricant (usually oil) forms between the shaft and the bearing surface. And here’s the clever part: that oil layer actually builds up pressure and gently lifts the shaft off the surface. This is called hydrodynamic lubrication, and it’s what keeps everything creeping smoothly and with very little wear.

Because they’re so reliable, journal bearings are found in all sorts of machines, from car engines and pumps to massive turbines and industrial equipment. If something spins rapidly and carries a load, chances are a journal bearing is at work, doing the hard work behind the scenes.

Key Parts of a Journal Bearing

The Bearing Surface (or Sleeve)

This is the inner surface against which the shaft spins. It doesn’t move, it just provides a smooth, sturdy path for the shaft. It’s usually made from metal or a coated material that resists wear.

Lubricant

A thin layer of oil (or sometimes grease) separates the shaft from the bearing surface. As the shaft rotates, this oil creates a cushion, lifting the shaft just enough to reduce friction. Some modern bearings even use self-lubricating materials, eliminating the need for oil.

Lubrication Grooves or Holes

They are not found in every bearing, but when present, they help the lubricant flow evenly, especially beneficial in high-speed or high-load applications.

Bearing Housing

This is the outer shell that holds everything together. It keeps the bearing in place, supports the structure, and helps manage the load from the rotating shaft.

Factors Influencing Effective Journal-Bearing Machining

Creating a high-quality journal bearing begins with more than just cutting metal, it starts with making informed choices and paying careful attention to detail. Let’s break down the key factors that make all the difference.

Material Matters

Choosing the right material is a crucial step, and it’s a big one. The material affects everything: how easily it can be machined, how long it lasts, and how well it withstands heat, pressure, and motion.

- Soft metals like bronze or Babbitt are easy to shape, but they require sharp tools and a light touch.

- Harder materials, such as Inconel, can withstand extreme heat but require specialized tooling.

- Modern composites can even lubricate themselves, eliminating the need for additional oil.

But it’s not just about strength or machinability, the material must also work well with the shaft and lubricant. If they’re not compatible, you risk issues like galling (metal sticking), wear, or breakdown over time.

Surface Finish – Smooth is Everything

A journal bearing only works well if it’s smooth on the inside, soft. That mirror-like finish (around Ra 0.2 to 0.4 microns) allows a thin oil film to form between the shaft and bearing. This film reduces friction, keeps things quiet, and prevents heat buildup. A rough surface? That invites wear and problems.

Heat Control – Stay Cool for Accuracy

Too much heat during machining causes the metal to expand, even slightly, and that can throw off critical measurements. To ensure accuracy, coolant systems are essential. Some setups even use infrared sensors to monitor temps in real-time. Managing heat is just as important as cutting.

Tool Condition – Sharp Tools, Clean Cuts

Dull or worn tools don’t just struggle, they can ruin a part. Uneven cuts, rough finishes, and rejected bearings are all signs your tools need attention. Keep tools sharp and check them regularly. A well-maintained tool means smoother results and fewer headaches.

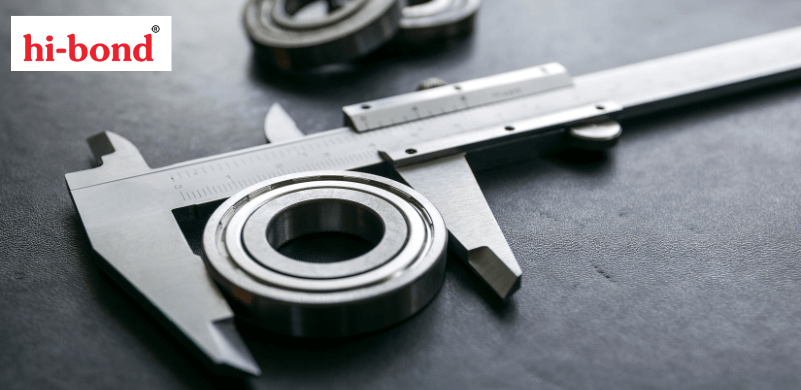

Dimensional Accuracy – Precision Pays Off

For the oil film to work correctly, the gap between the shaft and bearing, called the clearance, has to be just right. Too tight, and the shaft can bind. Too loose, and you get misalignment, excess friction, or premature wear.

A safe rule? 0.001 to 0.003 inches per inch of shaft diameter, depending on load, speed, and lubrication. Always double-check your specs. Even the most minor error here can throw everything off.

Machining a Journal Bearing: How Precision Takes Shape

Let’s be realistic, journal bearings may seem simple, but getting them right requires skill, patience, and a proper process. Every little step matters because these parts are designed to withstand intense pressure, speed, and heat without missing a beat.

That’s why partnering with the right industrial bearing suppliers is just as important, they provide not only quality materials but also the technical insight that supports precision machining from start to finish.

So, how do we transform a raw chunk of metal into something smooth, precise, and ready for work? Let’s walk through it.

Turning – Shaping the Basics

First things first, we start with turning. This is where the metal blank, the raw cylinder, gets its basic shape. A lathe or CNC machine spins it, and a cutting tool shaves it down into the rough size we need.

This is the foundation, and like any good foundation, it has to be solid. If we don’t get this part right, everything else will be off.

Sharp tools, steady speed, and plenty of coolant keep things cool and clean.

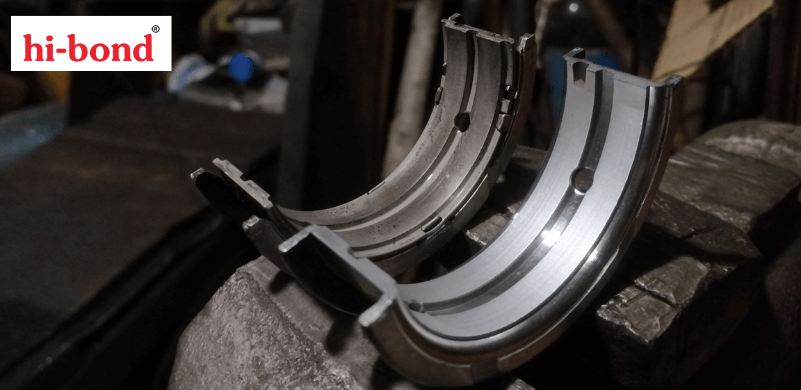

Boring – Nailing the Inside Fit

Once the outside is shaped, we move on to boring. This step is all about getting the inside diameter just right so the shaft can fit perfectly without being too tight or too loose.

Here’s the tricky part, if the tool used is too long or weak, it can bend slightly, which can throw off the entire cut.

Use strong, stable tools and regularly check your measurements as you progress.

Grinding – Time to Smooth Things Out

Now we get to grinding, and this is where things start to shine, literally. We use a fast-spinning abrasive wheel to remove the last tiny bits of metal gently.

Why? Because the smoother the surface, the better the oil sticks and flows, less friction, less heat, and way longer life for the bearing.

Faster wheel speeds, with good coolant, result in a smoother finish. For harder metals, CBN wheels are a game changer.

Honing – The Final Polish

Last step? Honing. This one’s like the cherry on top. It creates a delicate, cross-hatch pattern on the inside surface, something your eye might not notice, but your machine definitely will.

That pattern helps hold oil more effectively, which keeps the bearing cool and running smoothly, even under stress.

Sync up the tool’s spin and stroke to achieve an even, consistent finish.

Modern Manufacturing Techniques: Precision in Action

CNC Machining

CNC (Computer Numerical Control) machines are at the heart of bearing production today. They cut, shape, and finish parts using digital instructions, with incredible accuracy.

- Great for complex shapes and custom fits

- Delivers repeatable, high-quality results

- Reduces human error and boosts production speed

Automated Inspection

Once machined, parts are inspected using automated systems, such as laser scanners and coordinate measuring machines (CMMs). These tools instantly spot flaws and ensure every specification is met, no surprises later.

- Saves time and reduces waste

- Guarantees consistent quality

- Perfect for high-volume production

Smart Cooling & Lubrication

Machining generates heat, and excessive heat can compromise the accuracy of the process. That’s why modern setups utilize advanced coolant systems that automatically adjust to maintain stability.

- Prevents overheating

- Protects tool life

- Keeps tolerances tight

Robotics & Automation

Robotic arms now handle loading, unloading, and even in-line inspection. That means faster turnaround, fewer errors, and non-stop production.

- Ideal for large-scale manufacturing

- Improves efficiency and reliability

- Cuts down on manual labor

Digital Twin & Simulation

Before any physical part is manufactured, many companies utilize a digital twin, a virtual replica of the part and its associated process. This lets them test everything ahead of time.

- Predicts how parts will perform

- Helps optimize the process

- Saves time and material

3D Printing (Additive Manufacturing) – For Rapid Prototyping

3D printing isn’t yet suitable for mass production, but it’s ideal for prototyping or creating complex, custom designs. Want to test something fast without tooling up a factory line? This is how you do it.

- Great for intricate internal features (like built-in lubrication paths)

- Minimises waste

- Speeds up R&D cycles

Printed parts often require finishing touches, such as grinding or honing, and their material properties may differ from those of forged or machined parts.

Get the Perfect Journal Bearings From Hi-Bond Bearings Pvt Ltd for Smooth Machine Operation

Journal bearings might not grab the spotlight, but they’re the unsung heroes behind smooth, reliable machine performance. Getting them right takes attention to detail, precision machining, soft finishes, the right materials, and perfect clearances.

Experts from Hi-Bond Bearings Pvt Ltd help in providing the ideal journal bearings for your machinery.

When done correctly, journal bearings help everything run like a well-oiled jazz band.

So the next time an engine purrs or a turbine hums, remember, there’s a finely crafted journal bearing at work, thanks to the care and expertise of a good bearing manufacturing company.