Bearings play an important role in machinery by decreasing friction between moving parts, thereby improving efficiency and prolonging the lifespan of components. Among the various types of bearings available with Hi-bond Bearings Pvt. Ltd., journal bearings and rolling element bearings are two of the most widely used. While both are designed to handle loads and reduce friction, they operate differently and are suited for specific applications.

This blog post will analyze the fundamental differences between journal bearings and rolling element bearings, covering their design, advantages, limitations, and the factors that should be considered when choosing one over the other for your application.

A Brief Understanding of Journal Bearings

A journal bearing, also known as a sleeve bearing, is a simple bearing where a shaft rotates inside a bearing surface. It is typically made from materials like bronze, copper, or other metals, and it operates on a fluid film formed by the lubrication between the shaft and the bearing surface. Such bearings available with bearing manufacturers rely on lubricant flow to minimize metal-to-metal contact, thereby reducing friction and wear.

There are two main types:

Hydrodynamic Journal Bearings: These rely on the movement of the shaft to create a lubricating film between the shaft and the bearing surface.

Hydrostatic Journal Bearings: These use external pressure to supply lubrication and create a film between the surfaces, even when the shaft is stationary.

Journal bearings are widely used in applications with heavy loads and low to moderate speeds, such as engines, turbines, and compressors.

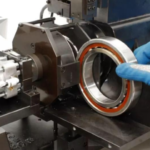

A Quick Idea on Rolling Element Bearings

Rolling element bearings, also called roller bearings, use rolling elements (like balls, rollers, or needles) to reduce friction between the bearing’s moving parts. Unlike journal bearings, rolling bearings feature elements that rotate between the inner and outer races, providing less friction than sliding components. The rolling elements allow for smoother operation and help reduce wear.

Their bearings types are many, including:

Ball Bearings: These bearings use spherical balls to support the load.

Cylindrical Roller Bearings: These use cylindrical rollers, which provide higher load-carrying capacity.

Needle Bearings: These use long, thin rollers to support radial and axial loads.

Rolling element bearings are used in applications where speed and precision are required like motors, gearboxes, and automotive parts.

Differences Between Journal Bearings and Rolling Element Bearings

While both types of bearings serve the same fundamental purpose, they differ greatly in their design, performance, and application. Let’s compare them based on various key factors:

1. Load Capacity:

The load bearing capacity refers to how much weight or force the bearing can support before it starts to wear out or fail.

Journal Bearings: These bearings are typically designed to handle larger, heavier loads. They excel in applications where high torque is required but the machine speed is low.

Rolling Element Bearings: They are designed to handle moderate to high radial loads, and some types are specifically designed for high axial load capabilities. They are often used in machinery where speed is more important than load-bearing capacity.

2. Speed and RPM Limits:

One of the most noteworthy differences between journal and rolling element bearings is their performance at high speeds.

Journal Bearings: Such bearings are ideal for applications that involve low to moderate speeds. While they can theoretically handle unlimited speeds, friction increases at higher rotational speeds, causing heat buildup and wear. As such, they are better suited for low-speed, high-load applications.

Rolling Element Bearings: These bearings perform better at higher speeds. Due to their rolling elements, they can handle faster rotations with less friction and heat. Roller bearings are widely used in high-speed applications like motors, fans, and turbines.

3. Temperature Sensitivity:

Temperature fluctuations can affect the performance of bearings, especially when they are subjected to high temperatures. Both journal and rolling element bearings have their temperature limits, but they handle heat differently.

Journal Bearings: They generally withstand higher temperatures due to their larger surface area and ability to dissipate heat. It makes them a better choice in applications where temperatures fluctuate or rise. However, the effectiveness of a journal bearing is still largely dependent on the lubrication used.

Rolling Element Bearings: These bearings tend to be more sensitive to temperature. While certain high-temperature versions of such bearings exist, they are still less capable of handling heat. Prolonged exposure to high temperatures reduces their lifespan and performance.

4. Bearing Maintenance Requirements:

The maintenance requirements of bearings depend on the type, design, and application.

Journal Bearings: These bearings require regular lubrication to ensure the shaft does not make direct contact with the bearing surface. Lubrication minimizes friction and prevents wear. These bearings must also be inspected regularly for signs of damage, and they require cleaning to remove contaminants that may cause wear.

Rolling Element Bearings: Roller bearings require less frequent maintenance because they are often sealed units with their own lubrication supply. However, they still need occasional inspection, especially if not sealed. Sealed types of bearings do not require as much attention, and they often last longer in clean, dry conditions.

5. Size and Installation Space Required:

The size and installation space available for bearings can greatly affect your choice.

Journal Bearings: They are typically larger and require more space, especially in high-load applications. Such bearings can handle larger dimensions, making them suitable for applications like turbines or large generators.

Rolling Element Bearings: Such bearings are more compact and used in tight spaces. They are generally smaller, making them ideal for smaller machinery or areas with limited space.

6. Cost and Availability of Bearings:

Cost plays a major role in selecting the right bearing for your application.

Journal Bearings: Such bearings are generally more affordable than rolling element bearings, particularly for applications where high-speed performance is not critical. They are relatively simpler to manufacture, which contributes to their lower cost.

Rolling Element Bearings: Due to their more complex design and manufacturing process, ball and roller bearings tend to be more expensive. However, their superior performance in high-speed applications as well as longer lifespan can make them more cost-effective in certain scenarios.

7. The Effect of Environmental Conditions:

Environmental factors such as humidity, dust, and vibrations can affect bearing performance.

Journal Bearings: These bearings are prone to damage from contaminants like dirt, dust, or moisture. While they can perform well in specific environments, they often require special sealing or lubrication to prevent contamination.

Rolling Element Bearings: Sealed bearings provide better protection from external contaminants, making them more suitable for harsh or dirty environments. They are often used in machinery exposed to dust, moisture, or vibrations. Roller bearings tend to perform excellently in harsh environments due to their sealing capabilities.

8. Assessing Quality Assurance and Standards:

Quality assurance ensures that bearings perform well and meet industry standards.

Journal Bearings: While these bearings are simpler in design, they still require strict manufacturing standards to meet specific applications’ performance needs. Organizations like ISO or AGMA often define these standards.

Rolling Element Bearings: These bearings are subject to similar quality standards. In fact, they are typically subject to more rigorous testing due to their complexity and performance requirements.

Both kinds of bearings should meet high-quality standards, but rolling element bearings may undergo more extensive testing due to their intricate design.

9. Bearing Design Flexibility:

Both journal and rolling element bearings come in a broad variety of designs to suit different applications.

Journal bearings: Though they are simpler, can be customized for heavy-duty, low-speed applications.

Rolling element bearings: They offer more design options, including sealed bearings, different load types, and various materials.

Consult Bearing Manufacturing Company to Choose The Right Bearing for Your Application!

Both journal and rolling element bearings serve important roles in industrial applications, each offering different advantages as per their specific needs of the machine. Journal bearings are best suited for heavy-load, low-speed environments, offering durability and better shock load resistance while rolling element bearings are ideal for high-speed, precision applications where reduced friction and compact size are essential.

The decision finally comes down to factors like load capacity, speed limits, temperature ranges, and maintenance requirements. By carefully considering these elements in the context of your machinery, you can consult the bearing manufacturing company for the right bearing solutions to ensure optimal performance, longevity, and cost-effectiveness for your application.